Key Insights

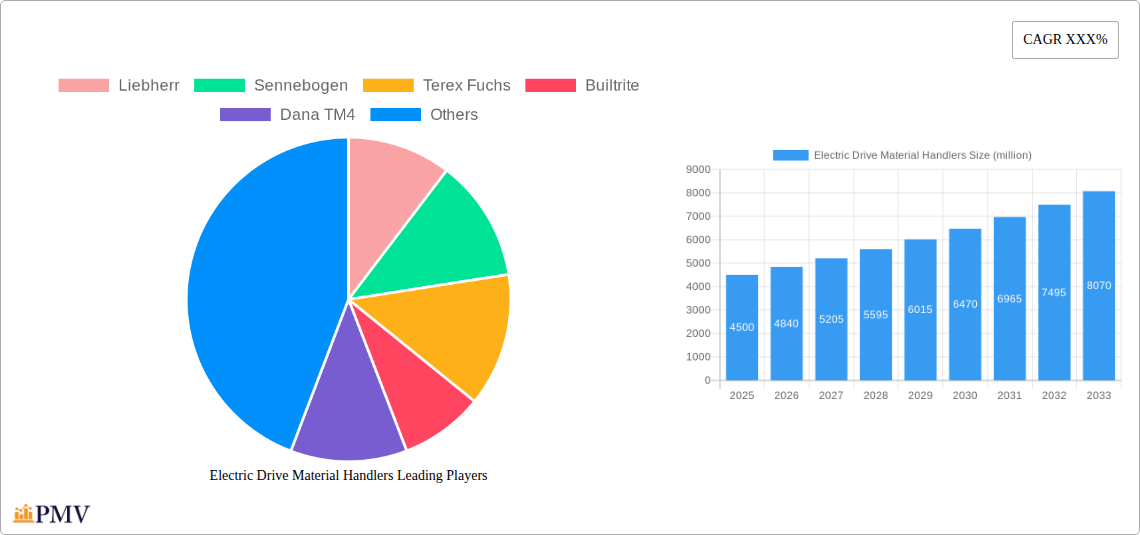

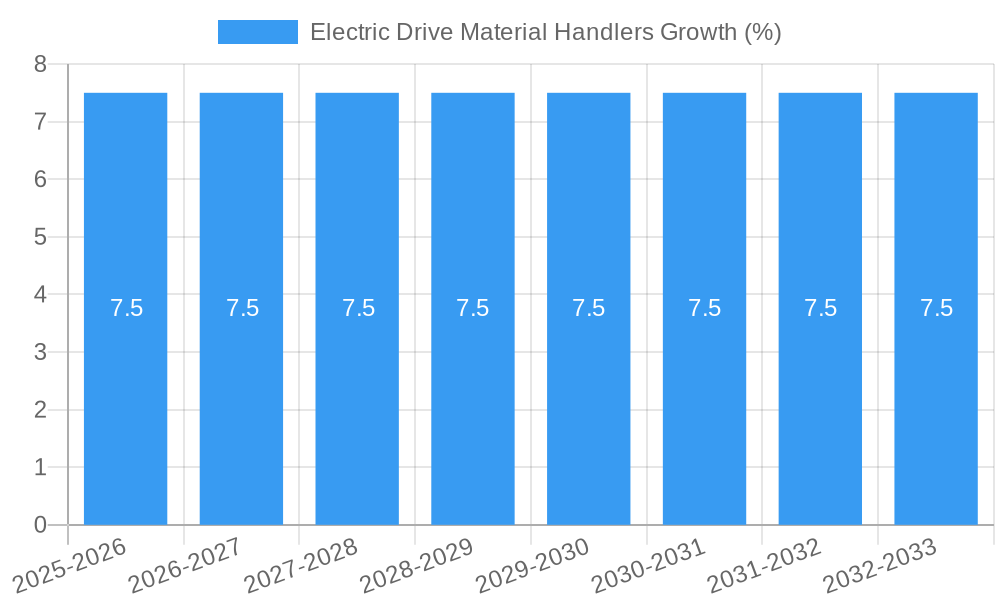

The Electric Drive Material Handlers market is poised for significant expansion, with an estimated market size of $4,500 million and a projected Compound Annual Growth Rate (CAGR) of 7.5% from 2025 to 2033. This robust growth is propelled by a confluence of factors, primarily the increasing adoption of sustainable and efficient material handling solutions across various industries. Key drivers include stringent environmental regulations aimed at reducing carbon emissions and noise pollution, compelling organizations to transition away from traditional diesel-powered equipment. Furthermore, the escalating operational costs associated with fossil fuels, coupled with advancements in battery technology and electric powertrain efficiency, are making electric material handlers a more economically viable and attractive option for businesses. The growing emphasis on workplace safety and automation within industrial settings also contributes to the market's upward trajectory, as electric handlers often offer enhanced control, precision, and integrated safety features. The demand is particularly strong in ports and storehouses, where continuous operation and large-scale material movement are paramount, necessitating reliable and eco-friendly solutions.

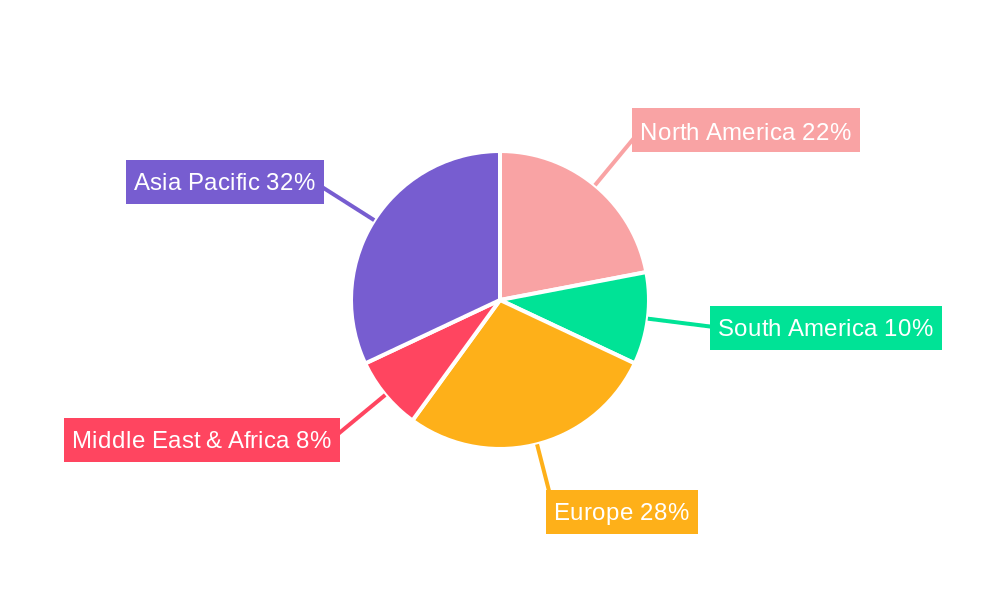

The market segmentation reveals a dynamic landscape, with the "Port" and "Storehouse" applications representing the largest and fastest-growing segments, respectively, reflecting the concentrated need for efficient and sustainable material handling in these critical infrastructure areas. In terms of type, mobile handlers are expected to dominate, driven by their flexibility and adaptability to diverse operational environments. While the market is characterized by strong growth, certain restraints exist, such as the initial high capital investment for electric machinery and the ongoing need for robust charging infrastructure. However, ongoing technological innovations are steadily addressing these challenges, with companies like Liebherr, Sennebogen, and Terex Fuchs leading the charge in developing advanced electric drive solutions. The Asia Pacific region, particularly China and India, is anticipated to be a key growth engine due to rapid industrialization and increasing environmental consciousness. The global shift towards electrification in material handling underscores a broader trend of industrial decarbonization and a move towards smarter, more sustainable operations.

This in-depth market research report provides a detailed examination of the global Electric Drive Material Handlers market, offering critical insights for stakeholders from 2019 to 2033. With a base year of 2025 and a forecast period extending to 2033, this study covers historical trends, current market dynamics, and future projections. The report meticulously analyzes various segments, including applications in Ports, Storehouses, Shopping Malls, and Other sectors, alongside types such as Mobile, Crawler, and Other material handlers. Key industry players like Liebherr, Sennebogen, Terex Fuchs, Builtrite, Dana TM4, JWF Technologies, Sprint Electric, Linde, WorldWide Electric, Sany, Rotobec, and Hoist Liftruck are profiled, with a focus on their strategic initiatives and market contributions. This report is an essential resource for understanding the evolving landscape of electric material handling solutions, driven by technological advancements and increasing environmental regulations.

Electric Drive Material Handlers Market Structure & Competitive Dynamics

The global Electric Drive Material Handlers market exhibits a moderate to high market concentration, with established players like Liebherr, Sennebogen, and Terex Fuchs dominating significant market share, estimated in the range of 20-30 million for leading entities. Innovation ecosystems are thriving, fueled by substantial investments in research and development by key manufacturers aiming to enhance battery technology, motor efficiency, and intelligent automation features. Regulatory frameworks, particularly those promoting sustainability and emissions reduction, are acting as significant growth accelerators, driving demand for electric solutions across various industries. Product substitutes, primarily traditional diesel-powered material handlers, are facing increasing pressure due to their higher operational costs and environmental impact. End-user trends are clearly shifting towards operational efficiency, reduced noise pollution, and lower total cost of ownership (TCO), making electric drive options highly attractive. Merger and acquisition (M&A) activities, while not widespread, are focused on consolidating technological expertise and expanding geographical reach. For instance, potential M&A deals are projected to be in the tens of millions, consolidating smaller innovative firms with larger established manufacturers. Understanding these dynamics is crucial for navigating the competitive landscape and capitalizing on emerging opportunities within the electric material handling sector.

Electric Drive Material Handlers Industry Trends & Insights

The Electric Drive Material Handlers industry is experiencing robust growth, projected at a Compound Annual Growth Rate (CAGR) of approximately 7-9% over the forecast period. This expansion is primarily driven by a confluence of technological advancements, increasing environmental consciousness, and supportive government policies. The transition from internal combustion engine (ICE) powered equipment to electric alternatives is a pivotal trend, spurred by escalating fuel costs and stringent emission regulations worldwide. Technological disruptions are at the forefront, with continuous improvements in battery technology, including higher energy density, faster charging capabilities, and extended lifespan, significantly reducing downtime and operational costs for end-users. Motor efficiency and control systems are also evolving, leading to enhanced performance and precise handling operations.

Consumer preferences are increasingly leaning towards electric material handlers due to their lower operational expenditures, owing to reduced maintenance needs and cheaper electricity compared to diesel fuel. Furthermore, the inherent advantages of electric motors, such as quieter operation and zero tailpipe emissions, are becoming critical factors, especially in indoor applications and urban environments, contributing to improved working conditions and compliance with noise and air quality standards. Market penetration of electric drive material handlers is steadily increasing, particularly in developed economies where environmental mandates are stricter and the infrastructure for charging is more developed.

Competitive dynamics are intensifying as both established manufacturers and new entrants vie for market share. Companies are investing heavily in product development to offer a wider range of electric models with enhanced features and competitive pricing. The development of advanced software for fleet management and predictive maintenance is also a key differentiator. The industry is witnessing a growing demand for specialized electric material handlers designed for specific applications, such as those used in ports for container handling, in large warehouses for efficient inventory management, and in specialized industrial settings. The integration of IoT and AI technologies is further enhancing the capabilities of these machines, enabling smarter operations and greater efficiency. The projected market size for electric drive material handlers is expected to reach over $15,000 million by 2033, showcasing a significant upward trajectory.

Dominant Markets & Segments in Electric Drive Material Handlers

The Port application segment stands out as a dominant force in the global Electric Drive Material Handlers market, driven by substantial investments in port modernization and the growing emphasis on sustainable logistics. Countries with major global trade hubs, such as China, the United States, and the European Union, are leading the adoption of electric material handlers within their port infrastructures.

- Port Application Drivers:

- Economic Policies: Government initiatives promoting green ports and reducing carbon footprints are a major catalyst. For instance, initiatives like the EU's Green Deal are pushing for electrification in maritime and port operations.

- Infrastructure Development: Ongoing upgrades to port facilities worldwide necessitate the adoption of advanced, efficient, and environmentally friendly equipment, including electric reach stackers, straddle carriers, and container handlers. The projected investment in port infrastructure over the forecast period is in the range of several hundred million dollars annually.

- Operational Efficiency Demands: Ports are high-volume operational environments where efficiency is paramount. Electric handlers offer quieter operations, reduced maintenance, and lower energy costs per lift, contributing to a lower total cost of ownership and improved throughput.

- Regulatory Compliance: Increasingly stringent emission standards at global and national levels are compelling port authorities to phase out diesel-powered machinery.

The Mobile type segment also holds significant dominance, particularly in applications requiring flexibility and versatility. The ability of mobile electric material handlers to quickly redeploy across different areas within a facility or to different sites makes them highly valuable in diverse operational settings.

- Mobile Type Drivers:

- Versatility and Adaptability: Electric forklifts, telehandlers, and skid steers are essential for various tasks in warehouses, construction sites, and manufacturing facilities, where mobility is key.

- Technological Advancements: Innovations in battery technology and electric powertrain design have made mobile electric handlers more powerful, with longer operating times and faster charging.

- Ease of Use and Maintenance: Many mobile electric handlers are designed for user-friendliness, with intuitive controls and reduced maintenance requirements compared to their ICE counterparts.

The Storehouse segment, encompassing warehouses and distribution centers, represents another substantial market. The need for efficient, emission-free material handling within enclosed spaces, coupled with the desire to reduce operational costs, makes electric material handlers a preferred choice. The projected market size for electric material handlers in this segment alone is estimated to be over $8,000 million by 2033.

- Storehouse Segment Drivers:

- Automation Integration: Electric material handlers are more amenable to integration with automation systems and smart warehouse technologies, enhancing inventory management and order fulfillment.

- Improved Indoor Air Quality: The absence of emissions is crucial for maintaining a healthy working environment in indoor storage facilities.

- Energy Cost Savings: Lower electricity prices compared to diesel fuel translate into significant operational cost savings for warehouse operators.

While Shopping Malls and "Other" applications are smaller segments, they represent niche growth opportunities, particularly for smaller, specialized electric material handlers. The overall dominance is clearly attributed to the large-scale, high-volume operations in Ports and the widespread utility in Storehouses and various mobile applications.

Electric Drive Material Handlers Product Innovations

Product innovations in the Electric Drive Material Handlers market are primarily focused on enhancing battery technology for extended runtimes and faster charging, improving motor efficiency for greater power and precision, and integrating smart technologies for enhanced operational control and safety. Manufacturers are developing specialized attachments and configurations to cater to niche applications within ports, warehouses, and other industrial settings. These innovations aim to reduce the total cost of ownership, increase productivity, and minimize environmental impact. Competitive advantages are being gained through superior battery management systems, advanced telematics for real-time monitoring, and robust design for demanding operational environments. The market is witnessing a trend towards lighter yet more powerful machines, optimized for energy consumption and ease of operation.

Report Segmentation & Scope

This report segments the Electric Drive Material Handlers market based on key application and type categories.

Application Segments:

- Port: Focuses on material handlers used in maritime ports for loading and unloading cargo, including reach stackers and straddle carriers. Market size projected at over $5,000 million by 2033, with a CAGR of 8.5%. Competitive dynamics are intense, with a focus on high-capacity and reliable machines.

- Storehouse: Encompasses electric forklifts, pallet trucks, and order pickers used in warehouses and distribution centers. Projected market size of over $8,000 million by 2033, with a CAGR of 7.8%. Key growth drivers include e-commerce expansion and warehouse automation.

- Shopping Mall: Includes smaller, specialized electric handlers for maintenance, logistics within retail complexes, and waste management. This is a niche segment with a projected market size of around $500 million by 2033, with a CAGR of 6.5%.

- Other: Covers various industrial applications, construction sites, and waste management facilities. Projected market size of over $1,500 million by 2033, with a CAGR of 7.2%.

Type Segments:

- Mobile: Includes wheeled material handlers like forklifts and telehandlers. This segment is expected to dominate, with a projected market size of over $12,000 million by 2033, driven by their versatility.

- Crawler: Refers to tracked material handlers, often used in rough terrain or heavy-duty applications. Projected market size of around $2,000 million by 2033, with a CAGR of 7.0%.

- Other: Encompasses specialized or less common types of electric material handlers. Projected market size of around $1,000 million by 2033, with a CAGR of 6.8%.

Key Drivers of Electric Drive Material Handlers Growth

The growth of the Electric Drive Material Handlers market is propelled by several interconnected factors. Technological advancements in battery technology, such as increased energy density and faster charging times, are making electric handlers more practical and efficient. Economic factors like rising fuel costs and a focus on reducing operational expenditures are making electric options more financially attractive. Furthermore, stringent environmental regulations globally, aiming to curb emissions and promote sustainability, are a significant driver, forcing industries to adopt cleaner alternatives. Government incentives and subsidies for purchasing electric machinery further bolster market expansion. The growing awareness of the benefits of reduced noise pollution and improved workplace safety in electric material handlers also contributes to their adoption.

Challenges in the Electric Drive Material Handlers Sector

Despite the promising growth, the Electric Drive Material Handlers sector faces certain challenges. The initial capital investment for electric material handlers can be higher compared to their diesel counterparts, posing a barrier for some businesses. Charging infrastructure availability and charging times remain a concern, especially for large-scale operations requiring continuous use. Battery lifespan and replacement costs are also factors that need careful consideration by end-users. Additionally, supply chain disruptions for key components, particularly batteries, can impact production and availability. Intense competition from established diesel manufacturers and the need for specialized training for maintenance personnel also present hurdles to widespread adoption. Overcoming these challenges will be crucial for unlocking the full market potential.

Leading Players in the Electric Drive Material Handlers Market

- Liebherr

- Sennebogen

- Terex Fuchs

- Builtrite

- Dana TM4

- JWF Technologies

- Sprint Electric

- Linde

- WorldWide Electric

- Sany

- Rotobec

- Hoist Liftruck

Key Developments in Electric Drive Material Handlers Sector

- 2023 Q4: Liebherr launched a new series of electric material handlers with improved battery technology and advanced safety features, targeting port and industrial applications.

- 2023 Q3: Sennebogen showcased its latest innovations in electric crawler material handlers, emphasizing enhanced energy efficiency and reduced environmental impact.

- 2023 Q2: Terex Fuchs introduced new charging solutions for their electric material handlers, aiming to minimize downtime for operators.

- 2023 Q1: Builtrite announced strategic partnerships to expand its dealer network for electric material handlers in North America.

- 2022 Q4: Dana TM4 reported significant advancements in its electric powertrain systems, offering higher torque and improved durability for material handling equipment.

- 2022 Q3: JWF Technologies developed a new modular battery system for electric material handlers, offering flexibility and scalability for different power requirements.

- 2022 Q2: Sprint Electric expanded its range of motor controllers designed for electric material handlers, focusing on precise control and energy optimization.

- 2022 Q1: Linde introduced a new generation of electric forklifts with enhanced ergonomics and intelligent control systems, improving operator comfort and efficiency.

- 2021 Q4: WorldWide Electric expanded its portfolio of electric motors for material handling applications, catering to a wider range of power and performance needs.

- 2021 Q3: Sany announced ambitious plans for expanding its electric material handler production capacity to meet growing global demand.

- 2021 Q2: Rotobec unveiled new electric-powered grapple attachments, enhancing the versatility of its material handling solutions.

- 2021 Q1: Hoist Liftruck introduced a new line of heavy-duty electric material handlers designed for demanding industrial environments.

Strategic Electric Drive Material Handlers Market Outlook

- 2023 Q4: Liebherr launched a new series of electric material handlers with improved battery technology and advanced safety features, targeting port and industrial applications.

- 2023 Q3: Sennebogen showcased its latest innovations in electric crawler material handlers, emphasizing enhanced energy efficiency and reduced environmental impact.

- 2023 Q2: Terex Fuchs introduced new charging solutions for their electric material handlers, aiming to minimize downtime for operators.

- 2023 Q1: Builtrite announced strategic partnerships to expand its dealer network for electric material handlers in North America.

- 2022 Q4: Dana TM4 reported significant advancements in its electric powertrain systems, offering higher torque and improved durability for material handling equipment.

- 2022 Q3: JWF Technologies developed a new modular battery system for electric material handlers, offering flexibility and scalability for different power requirements.

- 2022 Q2: Sprint Electric expanded its range of motor controllers designed for electric material handlers, focusing on precise control and energy optimization.

- 2022 Q1: Linde introduced a new generation of electric forklifts with enhanced ergonomics and intelligent control systems, improving operator comfort and efficiency.

- 2021 Q4: WorldWide Electric expanded its portfolio of electric motors for material handling applications, catering to a wider range of power and performance needs.

- 2021 Q3: Sany announced ambitious plans for expanding its electric material handler production capacity to meet growing global demand.

- 2021 Q2: Rotobec unveiled new electric-powered grapple attachments, enhancing the versatility of its material handling solutions.

- 2021 Q1: Hoist Liftruck introduced a new line of heavy-duty electric material handlers designed for demanding industrial environments.

Strategic Electric Drive Material Handlers Market Outlook

The strategic outlook for the Electric Drive Material Handlers market is exceptionally positive, characterized by sustained growth fueled by global sustainability initiatives and continuous technological innovation. Market players are focusing on expanding their product portfolios to include a wider range of electric models, catering to diverse applications and power requirements. Strategic collaborations and partnerships are crucial for developing integrated solutions, including advanced charging infrastructure and fleet management software. Investment in research and development for next-generation battery technologies and autonomous handling capabilities will be key to maintaining a competitive edge. Emerging markets, with their rapidly developing industrial sectors and increasing environmental consciousness, represent significant untapped potential. The transition towards electric mobility in material handling is not just an environmental imperative but a strategic business advantage, offering enhanced efficiency, reduced operational costs, and a smaller carbon footprint, thus paving the way for substantial future market growth.

Electric Drive Material Handlers Segmentation

-

1. Application

- 1.1. Port

- 1.2. Storehouse

- 1.3. Shopping Mall

- 1.4. Other

-

2. Type

- 2.1. Mobile

- 2.2. Crawler

- 2.3. Other

Electric Drive Material Handlers Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Electric Drive Material Handlers REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XXX% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Electric Drive Material Handlers Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Port

- 5.1.2. Storehouse

- 5.1.3. Shopping Mall

- 5.1.4. Other

- 5.2. Market Analysis, Insights and Forecast - by Type

- 5.2.1. Mobile

- 5.2.2. Crawler

- 5.2.3. Other

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Electric Drive Material Handlers Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Port

- 6.1.2. Storehouse

- 6.1.3. Shopping Mall

- 6.1.4. Other

- 6.2. Market Analysis, Insights and Forecast - by Type

- 6.2.1. Mobile

- 6.2.2. Crawler

- 6.2.3. Other

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Electric Drive Material Handlers Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Port

- 7.1.2. Storehouse

- 7.1.3. Shopping Mall

- 7.1.4. Other

- 7.2. Market Analysis, Insights and Forecast - by Type

- 7.2.1. Mobile

- 7.2.2. Crawler

- 7.2.3. Other

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Electric Drive Material Handlers Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Port

- 8.1.2. Storehouse

- 8.1.3. Shopping Mall

- 8.1.4. Other

- 8.2. Market Analysis, Insights and Forecast - by Type

- 8.2.1. Mobile

- 8.2.2. Crawler

- 8.2.3. Other

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Electric Drive Material Handlers Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Port

- 9.1.2. Storehouse

- 9.1.3. Shopping Mall

- 9.1.4. Other

- 9.2. Market Analysis, Insights and Forecast - by Type

- 9.2.1. Mobile

- 9.2.2. Crawler

- 9.2.3. Other

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Electric Drive Material Handlers Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Port

- 10.1.2. Storehouse

- 10.1.3. Shopping Mall

- 10.1.4. Other

- 10.2. Market Analysis, Insights and Forecast - by Type

- 10.2.1. Mobile

- 10.2.2. Crawler

- 10.2.3. Other

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 Liebherr

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Sennebogen

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Terex Fuchs

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Builtrite

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Dana TM4

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 JWF Technologies

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Sprint Electric

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Linde

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 WorldWide Electric

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Sany

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Rotobec

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Hoist Liftruck

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.1 Liebherr

List of Figures

- Figure 1: Global Electric Drive Material Handlers Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Electric Drive Material Handlers Revenue (million), by Application 2024 & 2032

- Figure 3: North America Electric Drive Material Handlers Revenue Share (%), by Application 2024 & 2032

- Figure 4: North America Electric Drive Material Handlers Revenue (million), by Type 2024 & 2032

- Figure 5: North America Electric Drive Material Handlers Revenue Share (%), by Type 2024 & 2032

- Figure 6: North America Electric Drive Material Handlers Revenue (million), by Country 2024 & 2032

- Figure 7: North America Electric Drive Material Handlers Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Electric Drive Material Handlers Revenue (million), by Application 2024 & 2032

- Figure 9: South America Electric Drive Material Handlers Revenue Share (%), by Application 2024 & 2032

- Figure 10: South America Electric Drive Material Handlers Revenue (million), by Type 2024 & 2032

- Figure 11: South America Electric Drive Material Handlers Revenue Share (%), by Type 2024 & 2032

- Figure 12: South America Electric Drive Material Handlers Revenue (million), by Country 2024 & 2032

- Figure 13: South America Electric Drive Material Handlers Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Electric Drive Material Handlers Revenue (million), by Application 2024 & 2032

- Figure 15: Europe Electric Drive Material Handlers Revenue Share (%), by Application 2024 & 2032

- Figure 16: Europe Electric Drive Material Handlers Revenue (million), by Type 2024 & 2032

- Figure 17: Europe Electric Drive Material Handlers Revenue Share (%), by Type 2024 & 2032

- Figure 18: Europe Electric Drive Material Handlers Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Electric Drive Material Handlers Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Electric Drive Material Handlers Revenue (million), by Application 2024 & 2032

- Figure 21: Middle East & Africa Electric Drive Material Handlers Revenue Share (%), by Application 2024 & 2032

- Figure 22: Middle East & Africa Electric Drive Material Handlers Revenue (million), by Type 2024 & 2032

- Figure 23: Middle East & Africa Electric Drive Material Handlers Revenue Share (%), by Type 2024 & 2032

- Figure 24: Middle East & Africa Electric Drive Material Handlers Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Electric Drive Material Handlers Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Electric Drive Material Handlers Revenue (million), by Application 2024 & 2032

- Figure 27: Asia Pacific Electric Drive Material Handlers Revenue Share (%), by Application 2024 & 2032

- Figure 28: Asia Pacific Electric Drive Material Handlers Revenue (million), by Type 2024 & 2032

- Figure 29: Asia Pacific Electric Drive Material Handlers Revenue Share (%), by Type 2024 & 2032

- Figure 30: Asia Pacific Electric Drive Material Handlers Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Electric Drive Material Handlers Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Electric Drive Material Handlers Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Electric Drive Material Handlers Revenue million Forecast, by Application 2019 & 2032

- Table 3: Global Electric Drive Material Handlers Revenue million Forecast, by Type 2019 & 2032

- Table 4: Global Electric Drive Material Handlers Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Electric Drive Material Handlers Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Electric Drive Material Handlers Revenue million Forecast, by Type 2019 & 2032

- Table 7: Global Electric Drive Material Handlers Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Electric Drive Material Handlers Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Electric Drive Material Handlers Revenue million Forecast, by Type 2019 & 2032

- Table 13: Global Electric Drive Material Handlers Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Electric Drive Material Handlers Revenue million Forecast, by Application 2019 & 2032

- Table 18: Global Electric Drive Material Handlers Revenue million Forecast, by Type 2019 & 2032

- Table 19: Global Electric Drive Material Handlers Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Electric Drive Material Handlers Revenue million Forecast, by Application 2019 & 2032

- Table 30: Global Electric Drive Material Handlers Revenue million Forecast, by Type 2019 & 2032

- Table 31: Global Electric Drive Material Handlers Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Electric Drive Material Handlers Revenue million Forecast, by Application 2019 & 2032

- Table 39: Global Electric Drive Material Handlers Revenue million Forecast, by Type 2019 & 2032

- Table 40: Global Electric Drive Material Handlers Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Electric Drive Material Handlers Revenue (million) Forecast, by Application 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the Electric Drive Material Handlers?

The projected CAGR is approximately XXX%.

2. Which companies are prominent players in the Electric Drive Material Handlers?

Key companies in the market include Liebherr, Sennebogen, Terex Fuchs, Builtrite, Dana TM4, JWF Technologies, Sprint Electric, Linde, WorldWide Electric, Sany, Rotobec, Hoist Liftruck.

3. What are the main segments of the Electric Drive Material Handlers?

The market segments include Application, Type.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX million as of 2022.

5. What are some drivers contributing to market growth?

N/A

6. What are the notable trends driving market growth?

N/A

7. Are there any restraints impacting market growth?

N/A

8. Can you provide examples of recent developments in the market?

N/A

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4250.00, USD 6375.00, and USD 8500.00 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "Electric Drive Material Handlers," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the Electric Drive Material Handlers report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the Electric Drive Material Handlers?

To stay informed about further developments, trends, and reports in the Electric Drive Material Handlers, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence