Key Insights

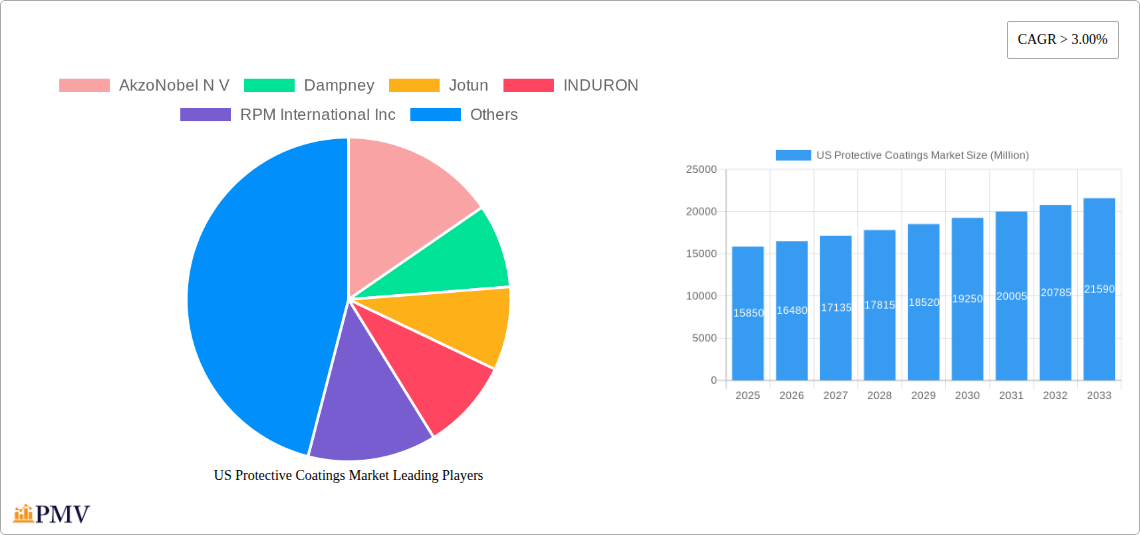

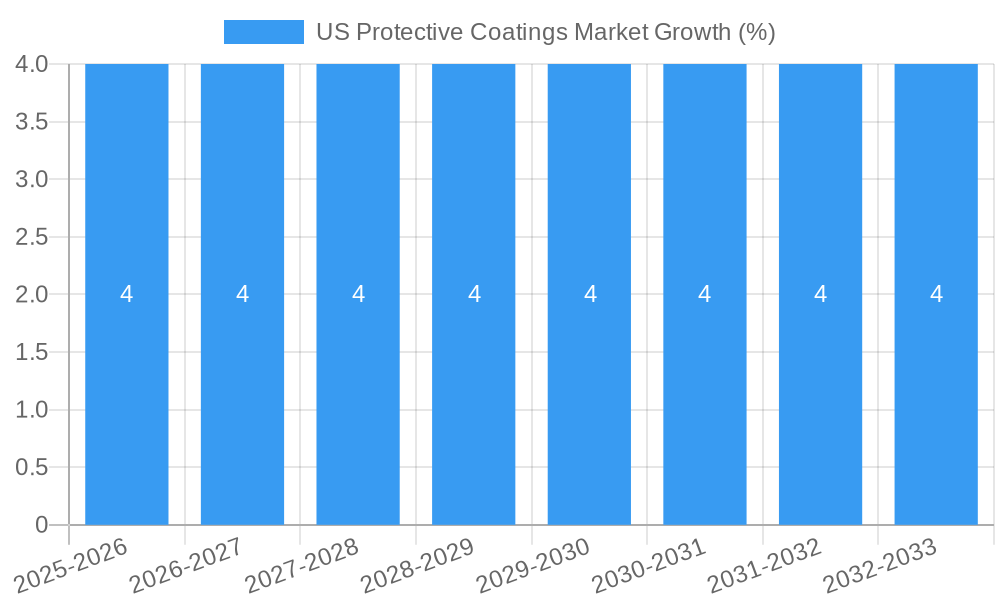

The US Protective Coatings Market is poised for robust growth, projected to reach an estimated $15.85 billion in 2025, with a Compound Annual Growth Rate (CAGR) of 4.02% through 2033. This expansion is fueled by substantial investments in infrastructure development, a burgeoning oil and gas sector, and the ongoing need for robust protection in mining and power industries. The demand for high-performance coatings that can withstand harsh environments, corrosive elements, and extreme temperatures is a primary driver. Advancements in coating technologies, particularly the increasing adoption of eco-friendly water-borne and high-solids solvent-borne coatings, are also contributing significantly to market dynamism. Furthermore, the continued emphasis on extending the lifespan and reducing maintenance costs of critical assets across various industrial sectors underscores the indispensable role of protective coatings.

Key trends shaping the US Protective Coatings Market include a strong shift towards sustainable and low-VOC (Volatile Organic Compound) formulations, driven by stringent environmental regulations and growing corporate responsibility initiatives. Innovations in application technologies, such as faster curing times and improved adhesion, are enhancing operational efficiency for end-users. The market is also witnessing the development of smart coatings with self-healing or anti-corrosion properties, offering enhanced durability and longevity. While the market benefits from strong demand, potential restraints include fluctuating raw material prices, particularly for resins and pigments, which can impact profitability. The competitive landscape is characterized by the presence of major global players alongside specialized regional manufacturers, all striving to innovate and capture market share through product differentiation and strategic partnerships.

This detailed report offers an in-depth analysis of the US Protective Coatings Market, a critical sector projected for significant expansion. Covering the historical period from 2019-2024 and a forecast period extending to 2033, with a base year of 2025, this report provides actionable insights for stakeholders seeking to navigate this dynamic landscape. Our comprehensive research leverages high-ranking SEO keywords to ensure maximum visibility and engagement for industry professionals, including manufacturers, suppliers, distributors, and investors. We explore market structure, competitive dynamics, industry trends, segment dominance, product innovations, growth drivers, challenges, leading players, key developments, and a strategic market outlook. The estimated market size is expected to reach $XX billion by 2025, with a projected CAGR of XX% during the forecast period.

US Protective Coatings Market Market Structure & Competitive Dynamics

The US Protective Coatings Market exhibits a moderately concentrated structure, characterized by the presence of both large multinational corporations and specialized regional players. Innovation ecosystems are driven by continuous research and development in advanced formulations, focusing on enhanced durability, environmental sustainability, and application efficiency. Key regulatory frameworks, such as EPA regulations and industry-specific standards, significantly influence product development and market entry. Product substitutes, including alternative corrosion-resistant materials and different coating technologies, pose a constant competitive challenge. End-user trends emphasize a growing demand for low-VOC (Volatile Organic Compound) and high-performance coatings that offer extended service life and reduced maintenance costs. Mergers and acquisitions (M&A) are a prominent feature of the market, facilitating consolidation, market share expansion, and access to new technologies. For instance, the acquisition of Mascoat Ltd and Verdia Inc. by Seal for Life Industries in January 2022, and The Protech Group's acquisition of Evotech Industrial Coatings' liquid coatings business in November 2022, highlight the ongoing consolidation activities. These strategic moves are shaping the competitive landscape, with key players like AkzoNobel N V, Dampney, Jotun, INDURON, RPM International Inc, DECO Coatings, PPG Industries Inc, Beckers Group, APV Coatings, Axalta Coating Systems, Heresite, Hempel A/S, Tnemec, The Sherwin Williams Company, US Coatings, MIPA SE vying for market dominance through strategic investments and portfolio diversification.

US Protective Coatings Market Industry Trends & Insights

The US Protective Coatings Market is experiencing robust growth, propelled by several interconnected industry trends. A primary driver is the burgeoning demand from infrastructure development projects, including bridges, highways, and public utilities, all requiring superior protection against corrosion and environmental degradation. The oil and gas industry, despite cyclical fluctuations, continues to be a significant end-user, demanding high-performance coatings for exploration, production, and refining facilities operating in harsh environments. Similarly, the mining sector relies heavily on protective coatings to safeguard equipment and structures from abrasive materials and corrosive chemicals. The power generation sector, encompassing traditional and renewable energy sources, also presents substantial opportunities, with protective coatings essential for maintaining turbines, transmission towers, and solar panel structures.

Technological disruptions are revolutionizing the market. The shift towards water-borne coatings is gaining momentum, driven by stricter environmental regulations and a growing preference for eco-friendly solutions. These coatings offer reduced VOC emissions, improved worker safety, and lower disposal costs. Powder coatings are also witnessing increased adoption due to their durability, efficiency, and ability to provide a seamless, high-quality finish. Advancements in nanotechnology and smart coatings are further enhancing performance, offering self-healing properties, anti-microbial functionalities, and enhanced UV resistance.

Consumer preferences are evolving towards sustainability and long-term value. End-users are increasingly seeking protective coatings that not only offer superior protection but also contribute to energy efficiency and reduce the overall lifecycle cost of assets. This includes a demand for coatings with extended warranties and lower maintenance requirements.

Competitive dynamics are intensifying, with manufacturers focusing on product differentiation, strategic partnerships, and market expansion. The US Protective Coatings Market is characterized by intense price competition, particularly in mature segments. However, innovation in specialized high-performance coatings, catering to niche applications within industries like aerospace and marine, offers higher profit margins. The market penetration of advanced coating technologies is steadily increasing, driven by performance benefits and regulatory mandates. The overall market size is projected to reach $XX billion by 2025, with a projected CAGR of XX% during the forecast period, underscoring the significant growth potential and evolving landscape of the US Protective Coatings Market.

Dominant Markets & Segments in US Protective Coatings Market

The US Protective Coatings Market is segmented across various resin types, technologies, and end-user industries, each exhibiting distinct growth trajectories and dominance factors.

Resin Type Dominance:

- Epoxy Resin: This segment holds significant dominance due to its exceptional adhesion, chemical resistance, and mechanical strength. Epoxy coatings are widely used in industrial applications, including oil and gas pipelines, chemical processing plants, and marine structures, where extreme durability and corrosion resistance are paramount. The demand for high-solids epoxy formulations is particularly strong, aligning with environmental regulations.

- Polyurethane Resin: Polyurethanes are favored for their excellent flexibility, UV resistance, and abrasion resistance. They are extensively employed in the infrastructure sector for bridges, roadways, and architectural coatings, as well as in the automotive and aerospace industries. The demand for polyurethane coatings is bolstered by their ability to withstand harsh weather conditions and maintain aesthetic appeal.

- Acrylic Resin: Acrylic coatings offer good weatherability, color retention, and fast drying times. They are prevalent in architectural coatings, industrial maintenance, and OEM applications. The increasing focus on low-VOC acrylic formulations is driving growth in this segment.

- Alkyd Resin: While historically dominant, alkyd coatings are seeing a gradual decline in certain industrial applications due to their VOC content. However, they remain relevant in some general industrial and maintenance coatings due to their cost-effectiveness and ease of application.

- Polyester Resin: Polyester resins are utilized in powder coatings and coil coatings, offering good hardness, flexibility, and chemical resistance. They find applications in appliances, metal furniture, and building components.

- Other Resin Types: This category includes specialized resins like silicone, fluoropolymer, and vinyl ester, which cater to niche applications demanding extreme temperature resistance, specific chemical inertness, or exceptional longevity.

Technology Dominance:

- Solvent Borne Coatings: Despite environmental concerns, solvent-borne coatings continue to hold a significant market share due to their established performance characteristics and cost-effectiveness in certain industrial applications. However, their dominance is gradually being challenged by more sustainable alternatives.

- Water Borne Coatings: This segment is experiencing rapid growth, driven by stringent environmental regulations and a consumer preference for eco-friendly products. Water-borne coatings offer lower VOC emissions, reduced flammability, and easier cleanup, making them increasingly attractive across various end-user industries.

- Powder Coatings: Powder coatings are gaining traction due to their high transfer efficiency, minimal waste, and ability to deliver a durable, high-quality finish. They are widely used in the appliance, automotive, and general industrial sectors. The development of low-temperature curing powder coatings is further expanding their application range.

- Other Technologies: This includes advancements like UV-curable coatings and high-solids formulations, which offer specific performance advantages for specialized applications.

End-user Industry Dominance:

- Infrastructure: This sector is a dominant force in the US Protective Coatings Market, fueled by ongoing government investments in repairing and upgrading roads, bridges, public buildings, and utilities. The need for long-lasting protection against corrosion and environmental factors makes this a key growth engine.

- Oil and Gas: This industry remains a significant consumer of protective coatings, demanding high-performance solutions for pipelines, offshore platforms, storage tanks, and refining facilities. The need to protect assets from harsh chemicals, extreme temperatures, and corrosive environments drives consistent demand.

- Power: The power generation sector, including both traditional and renewable energy infrastructure, requires robust protective coatings for turbines, transmission towers, substations, and solar panel installations. The longevity and reliability of these assets depend heavily on effective corrosion and weather protection.

- Mining: The mining industry utilizes protective coatings to safeguard heavy machinery, processing equipment, and structural components from abrasive wear, chemical exposure, and corrosive elements inherent in mining operations.

- Other End-user Industries: This broad category encompasses diverse sectors like marine, aerospace, transportation, manufacturing, and general industrial maintenance, each contributing to the overall market demand with specific coating requirements.

The dominance of these segments is influenced by economic policies supporting infrastructure development, technological advancements in coating formulations, and evolving environmental regulations that favor sustainable solutions.

US Protective Coatings Market Product Innovations

Product innovation in the US Protective Coatings Market is primarily focused on enhancing performance characteristics, sustainability, and application efficiency. Manufacturers are developing advanced formulations, such as self-healing coatings that can autonomously repair minor damages, extending the lifespan of protected assets and reducing maintenance cycles. Innovations in nanotechnology are leading to coatings with superior abrasion resistance, enhanced UV protection, and anti-microbial properties. The drive towards eco-friendly solutions is evident in the development of low-VOC and zero-VOC coatings, including water-borne and powder coating technologies, that minimize environmental impact and improve worker safety. Smart coatings with integrated sensors for monitoring corrosion or structural integrity are also emerging, offering predictive maintenance capabilities. These product developments are directly addressing the growing demand for durable, sustainable, and technologically advanced protective solutions across various industries.

Report Segmentation & Scope

This report meticulously segments the US Protective Coatings Market to provide granular insights into its various facets.

- Resin Type: The market is analyzed across Epoxy, Acrylic, Alkyd, Polyurethane, Polyester, and Other Resin Types. Each segment's market size and growth projections are detailed, considering the unique performance attributes and application suitability of each resin. For instance, the Epoxy segment is projected to reach $X billion by 2033 with a CAGR of X%, driven by its superior chemical resistance.

- Technology: The report categorizes the market by Water Borne Coatings, Solvent Borne Coatings, Powder Coatings, and Other Technologies. The dominance of water-borne and powder coatings due to environmental concerns is highlighted, with growth projections reflecting this trend. Water Borne Coatings are expected to grow at X% CAGR, reaching $Y billion by 2033.

- End-user Industry: Key segments include Oil and Gas, Mining, Power, Infrastructure, and Other End-user Industries. Detailed analysis of the market size and competitive dynamics within each end-user sector is provided, emphasizing the growth drivers and specific coating requirements. The Infrastructure segment is projected to be the largest by market size, with an estimated $Z billion by 2033.

Key Drivers of US Protective Coatings Market Growth

Several key factors are propelling the growth of the US Protective Coatings Market. Infrastructure development and repair initiatives represent a significant driver, with government spending on bridges, roads, and public utilities creating sustained demand for durable protective coatings. The stringent regulatory landscape, particularly concerning environmental protection and worker safety, is a major catalyst for the adoption of low-VOC and eco-friendly coating technologies, such as water-borne and powder coatings. The increasing need for asset longevity and reduced maintenance costs across various industries, including oil and gas, mining, and power generation, is driving the demand for high-performance and long-lasting protective solutions. Furthermore, technological advancements in coating formulations, leading to enhanced properties like superior corrosion resistance, UV stability, and faster curing times, are opening up new application opportunities and fueling market expansion.

Challenges in the US Protective Coatings Market Sector

Despite its robust growth, the US Protective Coatings Market faces several challenges. Volatile raw material prices, particularly for petrochemical-derived components, can significantly impact profit margins and pricing strategies. The increasingly stringent environmental regulations require continuous investment in R&D for compliance and may lead to higher production costs for certain formulations. Supply chain disruptions, as witnessed in recent years, can affect the availability and cost of raw materials and finished products. Intense competition among established players and emerging manufacturers can lead to price pressures and market fragmentation. Furthermore, the labor shortage in skilled application trades can pose a challenge to the timely and effective implementation of protective coating systems.

Leading Players in the US Protective Coatings Market Market

- AkzoNobel N V

- Dampney

- Jotun

- INDURON

- RPM International Inc

- DECO Coatings

- PPG Industries Inc

- Beckers Group

- APV Coatings

- Axalta Coating Systems

- Heresite

- Hempel A/S

- Tnemec

- The Sherwin Williams Company

- US Coatings

- MIPA SE

Key Developments in US Protective Coatings Market Sector

- January 2022: Seal for Life Industries, a prominent paints and coatings manufacturer, strategically acquired two privately owned industrial coatings companies based out of the United States, namely Mascoat Ltd and Verdia Inc. This move significantly expanded Seal for Life's product portfolio and geographical reach within the US market, strengthening its position in specialized industrial coating solutions.

- November 2022: The Protech Group successfully acquired the liquid coatings business from Evotech Industrial Coatings, a Canadian-based coating manufacturer. This acquisition enhanced The Protech Group's capabilities in liquid coatings and broadened its market presence, particularly in North America, by integrating Evotech's established product lines and customer base.

Strategic US Protective Coatings Market Market Outlook

- January 2022: Seal for Life Industries, a prominent paints and coatings manufacturer, strategically acquired two privately owned industrial coatings companies based out of the United States, namely Mascoat Ltd and Verdia Inc. This move significantly expanded Seal for Life's product portfolio and geographical reach within the US market, strengthening its position in specialized industrial coating solutions.

- November 2022: The Protech Group successfully acquired the liquid coatings business from Evotech Industrial Coatings, a Canadian-based coating manufacturer. This acquisition enhanced The Protech Group's capabilities in liquid coatings and broadened its market presence, particularly in North America, by integrating Evotech's established product lines and customer base.

Strategic US Protective Coatings Market Market Outlook

The strategic outlook for the US Protective Coatings Market is highly optimistic, driven by sustained demand from critical sectors and a continuous push for innovation. The ongoing infrastructure renewal projects, coupled with the energy sector's persistent need for asset protection, will serve as consistent growth accelerators. The increasing emphasis on sustainability and the regulatory push towards environmentally friendly solutions will further bolster the market share of water-borne and powder coatings. Investments in R&D for advanced, high-performance coatings with enhanced durability and specialized functionalities, such as self-healing and smart coatings, will create significant market opportunities. Strategic partnerships, mergers, and acquisitions will continue to shape the competitive landscape, enabling companies to expand their product portfolios, gain market access, and leverage technological advancements. Overall, the US Protective Coatings Market is poised for significant and sustained growth, offering lucrative opportunities for players who can adapt to evolving technological demands and prioritize sustainable solutions.

US Protective Coatings Market Segmentation

-

1. Resin Type

- 1.1. Epoxy

- 1.2. Acrylic

- 1.3. Alkyd

- 1.4. Polyurethane

- 1.5. Polyester

- 1.6. Other Resin Types

-

2. Technology

- 2.1. Water Borne Coatings

- 2.2. Solvent Borne Coatings

- 2.3. Powder Coatings

- 2.4. Other Technologies

-

3. End-user Industry

- 3.1. Oil and Gas

- 3.2. Mining

- 3.3. Power

- 3.4. Infrastructure

- 3.5. Other End-user Industries

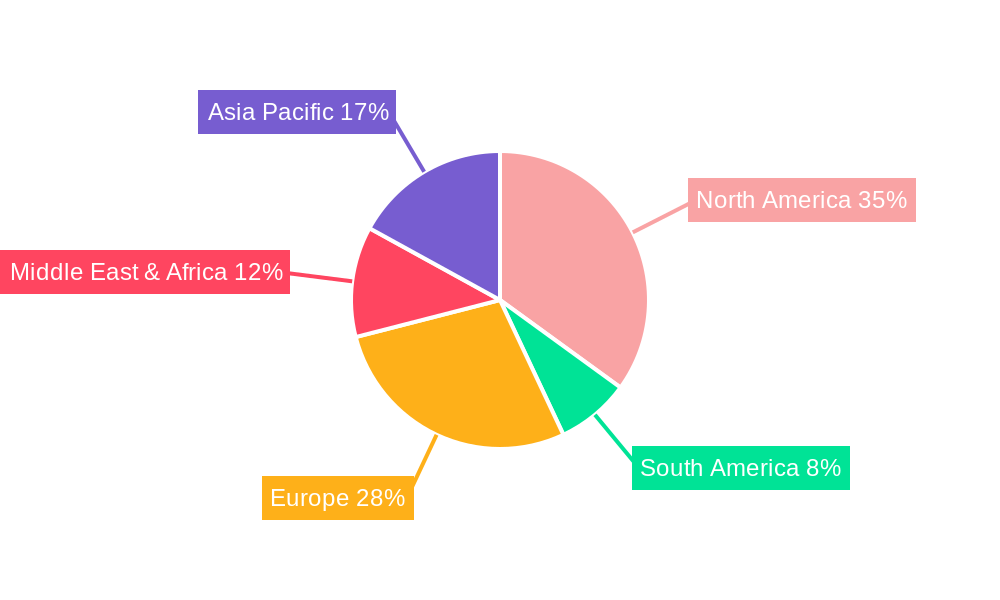

US Protective Coatings Market Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

US Protective Coatings Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 4.02% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increasing Activity in the Oil and Gas Sector; Infrastructure sector to Fuel in the Demand for Protective Coatings

- 3.3. Market Restrains

- 3.3.1. Price Hikes of Raw Materials; Other Restraints

- 3.4. Market Trends

- 3.4.1. Increasing Activity in the Oil and Gas Sector

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Resin Type

- 5.1.1. Epoxy

- 5.1.2. Acrylic

- 5.1.3. Alkyd

- 5.1.4. Polyurethane

- 5.1.5. Polyester

- 5.1.6. Other Resin Types

- 5.2. Market Analysis, Insights and Forecast - by Technology

- 5.2.1. Water Borne Coatings

- 5.2.2. Solvent Borne Coatings

- 5.2.3. Powder Coatings

- 5.2.4. Other Technologies

- 5.3. Market Analysis, Insights and Forecast - by End-user Industry

- 5.3.1. Oil and Gas

- 5.3.2. Mining

- 5.3.3. Power

- 5.3.4. Infrastructure

- 5.3.5. Other End-user Industries

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. North America

- 5.4.2. South America

- 5.4.3. Europe

- 5.4.4. Middle East & Africa

- 5.4.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Resin Type

- 6. North America US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Resin Type

- 6.1.1. Epoxy

- 6.1.2. Acrylic

- 6.1.3. Alkyd

- 6.1.4. Polyurethane

- 6.1.5. Polyester

- 6.1.6. Other Resin Types

- 6.2. Market Analysis, Insights and Forecast - by Technology

- 6.2.1. Water Borne Coatings

- 6.2.2. Solvent Borne Coatings

- 6.2.3. Powder Coatings

- 6.2.4. Other Technologies

- 6.3. Market Analysis, Insights and Forecast - by End-user Industry

- 6.3.1. Oil and Gas

- 6.3.2. Mining

- 6.3.3. Power

- 6.3.4. Infrastructure

- 6.3.5. Other End-user Industries

- 6.1. Market Analysis, Insights and Forecast - by Resin Type

- 7. South America US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Resin Type

- 7.1.1. Epoxy

- 7.1.2. Acrylic

- 7.1.3. Alkyd

- 7.1.4. Polyurethane

- 7.1.5. Polyester

- 7.1.6. Other Resin Types

- 7.2. Market Analysis, Insights and Forecast - by Technology

- 7.2.1. Water Borne Coatings

- 7.2.2. Solvent Borne Coatings

- 7.2.3. Powder Coatings

- 7.2.4. Other Technologies

- 7.3. Market Analysis, Insights and Forecast - by End-user Industry

- 7.3.1. Oil and Gas

- 7.3.2. Mining

- 7.3.3. Power

- 7.3.4. Infrastructure

- 7.3.5. Other End-user Industries

- 7.1. Market Analysis, Insights and Forecast - by Resin Type

- 8. Europe US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Resin Type

- 8.1.1. Epoxy

- 8.1.2. Acrylic

- 8.1.3. Alkyd

- 8.1.4. Polyurethane

- 8.1.5. Polyester

- 8.1.6. Other Resin Types

- 8.2. Market Analysis, Insights and Forecast - by Technology

- 8.2.1. Water Borne Coatings

- 8.2.2. Solvent Borne Coatings

- 8.2.3. Powder Coatings

- 8.2.4. Other Technologies

- 8.3. Market Analysis, Insights and Forecast - by End-user Industry

- 8.3.1. Oil and Gas

- 8.3.2. Mining

- 8.3.3. Power

- 8.3.4. Infrastructure

- 8.3.5. Other End-user Industries

- 8.1. Market Analysis, Insights and Forecast - by Resin Type

- 9. Middle East & Africa US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Resin Type

- 9.1.1. Epoxy

- 9.1.2. Acrylic

- 9.1.3. Alkyd

- 9.1.4. Polyurethane

- 9.1.5. Polyester

- 9.1.6. Other Resin Types

- 9.2. Market Analysis, Insights and Forecast - by Technology

- 9.2.1. Water Borne Coatings

- 9.2.2. Solvent Borne Coatings

- 9.2.3. Powder Coatings

- 9.2.4. Other Technologies

- 9.3. Market Analysis, Insights and Forecast - by End-user Industry

- 9.3.1. Oil and Gas

- 9.3.2. Mining

- 9.3.3. Power

- 9.3.4. Infrastructure

- 9.3.5. Other End-user Industries

- 9.1. Market Analysis, Insights and Forecast - by Resin Type

- 10. Asia Pacific US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Resin Type

- 10.1.1. Epoxy

- 10.1.2. Acrylic

- 10.1.3. Alkyd

- 10.1.4. Polyurethane

- 10.1.5. Polyester

- 10.1.6. Other Resin Types

- 10.2. Market Analysis, Insights and Forecast - by Technology

- 10.2.1. Water Borne Coatings

- 10.2.2. Solvent Borne Coatings

- 10.2.3. Powder Coatings

- 10.2.4. Other Technologies

- 10.3. Market Analysis, Insights and Forecast - by End-user Industry

- 10.3.1. Oil and Gas

- 10.3.2. Mining

- 10.3.3. Power

- 10.3.4. Infrastructure

- 10.3.5. Other End-user Industries

- 10.1. Market Analysis, Insights and Forecast - by Resin Type

- 11. Northeast US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 12. Southeast US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 13. Midwest US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 14. Southwest US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 15. West US Protective Coatings Market Analysis, Insights and Forecast, 2019-2031

- 16. Competitive Analysis

- 16.1. Global Market Share Analysis 2024

- 16.2. Company Profiles

- 16.2.1 AkzoNobel N V

- 16.2.1.1. Overview

- 16.2.1.2. Products

- 16.2.1.3. SWOT Analysis

- 16.2.1.4. Recent Developments

- 16.2.1.5. Financials (Based on Availability)

- 16.2.2 Dampney

- 16.2.2.1. Overview

- 16.2.2.2. Products

- 16.2.2.3. SWOT Analysis

- 16.2.2.4. Recent Developments

- 16.2.2.5. Financials (Based on Availability)

- 16.2.3 Jotun

- 16.2.3.1. Overview

- 16.2.3.2. Products

- 16.2.3.3. SWOT Analysis

- 16.2.3.4. Recent Developments

- 16.2.3.5. Financials (Based on Availability)

- 16.2.4 INDURON

- 16.2.4.1. Overview

- 16.2.4.2. Products

- 16.2.4.3. SWOT Analysis

- 16.2.4.4. Recent Developments

- 16.2.4.5. Financials (Based on Availability)

- 16.2.5 RPM International Inc

- 16.2.5.1. Overview

- 16.2.5.2. Products

- 16.2.5.3. SWOT Analysis

- 16.2.5.4. Recent Developments

- 16.2.5.5. Financials (Based on Availability)

- 16.2.6 DECO Coatings

- 16.2.6.1. Overview

- 16.2.6.2. Products

- 16.2.6.3. SWOT Analysis

- 16.2.6.4. Recent Developments

- 16.2.6.5. Financials (Based on Availability)

- 16.2.7 PPG Industries Inc

- 16.2.7.1. Overview

- 16.2.7.2. Products

- 16.2.7.3. SWOT Analysis

- 16.2.7.4. Recent Developments

- 16.2.7.5. Financials (Based on Availability)

- 16.2.8 Beckers Group

- 16.2.8.1. Overview

- 16.2.8.2. Products

- 16.2.8.3. SWOT Analysis

- 16.2.8.4. Recent Developments

- 16.2.8.5. Financials (Based on Availability)

- 16.2.9 APV Coatings

- 16.2.9.1. Overview

- 16.2.9.2. Products

- 16.2.9.3. SWOT Analysis

- 16.2.9.4. Recent Developments

- 16.2.9.5. Financials (Based on Availability)

- 16.2.10 Axalta Coating Systems

- 16.2.10.1. Overview

- 16.2.10.2. Products

- 16.2.10.3. SWOT Analysis

- 16.2.10.4. Recent Developments

- 16.2.10.5. Financials (Based on Availability)

- 16.2.11 Heresite

- 16.2.11.1. Overview

- 16.2.11.2. Products

- 16.2.11.3. SWOT Analysis

- 16.2.11.4. Recent Developments

- 16.2.11.5. Financials (Based on Availability)

- 16.2.12 Hempel A/S

- 16.2.12.1. Overview

- 16.2.12.2. Products

- 16.2.12.3. SWOT Analysis

- 16.2.12.4. Recent Developments

- 16.2.12.5. Financials (Based on Availability)

- 16.2.13 Tnemec

- 16.2.13.1. Overview

- 16.2.13.2. Products

- 16.2.13.3. SWOT Analysis

- 16.2.13.4. Recent Developments

- 16.2.13.5. Financials (Based on Availability)

- 16.2.14 The Sherwin Williams Company

- 16.2.14.1. Overview

- 16.2.14.2. Products

- 16.2.14.3. SWOT Analysis

- 16.2.14.4. Recent Developments

- 16.2.14.5. Financials (Based on Availability)

- 16.2.15 US Coatings*List Not Exhaustive

- 16.2.15.1. Overview

- 16.2.15.2. Products

- 16.2.15.3. SWOT Analysis

- 16.2.15.4. Recent Developments

- 16.2.15.5. Financials (Based on Availability)

- 16.2.16 MIPA SE

- 16.2.16.1. Overview

- 16.2.16.2. Products

- 16.2.16.3. SWOT Analysis

- 16.2.16.4. Recent Developments

- 16.2.16.5. Financials (Based on Availability)

- 16.2.1 AkzoNobel N V

List of Figures

- Figure 1: Global US Protective Coatings Market Revenue Breakdown (undefined, %) by Region 2024 & 2032

- Figure 2: United states US Protective Coatings Market Revenue (undefined), by Country 2024 & 2032

- Figure 3: United states US Protective Coatings Market Revenue Share (%), by Country 2024 & 2032

- Figure 4: North America US Protective Coatings Market Revenue (undefined), by Resin Type 2024 & 2032

- Figure 5: North America US Protective Coatings Market Revenue Share (%), by Resin Type 2024 & 2032

- Figure 6: North America US Protective Coatings Market Revenue (undefined), by Technology 2024 & 2032

- Figure 7: North America US Protective Coatings Market Revenue Share (%), by Technology 2024 & 2032

- Figure 8: North America US Protective Coatings Market Revenue (undefined), by End-user Industry 2024 & 2032

- Figure 9: North America US Protective Coatings Market Revenue Share (%), by End-user Industry 2024 & 2032

- Figure 10: North America US Protective Coatings Market Revenue (undefined), by Country 2024 & 2032

- Figure 11: North America US Protective Coatings Market Revenue Share (%), by Country 2024 & 2032

- Figure 12: South America US Protective Coatings Market Revenue (undefined), by Resin Type 2024 & 2032

- Figure 13: South America US Protective Coatings Market Revenue Share (%), by Resin Type 2024 & 2032

- Figure 14: South America US Protective Coatings Market Revenue (undefined), by Technology 2024 & 2032

- Figure 15: South America US Protective Coatings Market Revenue Share (%), by Technology 2024 & 2032

- Figure 16: South America US Protective Coatings Market Revenue (undefined), by End-user Industry 2024 & 2032

- Figure 17: South America US Protective Coatings Market Revenue Share (%), by End-user Industry 2024 & 2032

- Figure 18: South America US Protective Coatings Market Revenue (undefined), by Country 2024 & 2032

- Figure 19: South America US Protective Coatings Market Revenue Share (%), by Country 2024 & 2032

- Figure 20: Europe US Protective Coatings Market Revenue (undefined), by Resin Type 2024 & 2032

- Figure 21: Europe US Protective Coatings Market Revenue Share (%), by Resin Type 2024 & 2032

- Figure 22: Europe US Protective Coatings Market Revenue (undefined), by Technology 2024 & 2032

- Figure 23: Europe US Protective Coatings Market Revenue Share (%), by Technology 2024 & 2032

- Figure 24: Europe US Protective Coatings Market Revenue (undefined), by End-user Industry 2024 & 2032

- Figure 25: Europe US Protective Coatings Market Revenue Share (%), by End-user Industry 2024 & 2032

- Figure 26: Europe US Protective Coatings Market Revenue (undefined), by Country 2024 & 2032

- Figure 27: Europe US Protective Coatings Market Revenue Share (%), by Country 2024 & 2032

- Figure 28: Middle East & Africa US Protective Coatings Market Revenue (undefined), by Resin Type 2024 & 2032

- Figure 29: Middle East & Africa US Protective Coatings Market Revenue Share (%), by Resin Type 2024 & 2032

- Figure 30: Middle East & Africa US Protective Coatings Market Revenue (undefined), by Technology 2024 & 2032

- Figure 31: Middle East & Africa US Protective Coatings Market Revenue Share (%), by Technology 2024 & 2032

- Figure 32: Middle East & Africa US Protective Coatings Market Revenue (undefined), by End-user Industry 2024 & 2032

- Figure 33: Middle East & Africa US Protective Coatings Market Revenue Share (%), by End-user Industry 2024 & 2032

- Figure 34: Middle East & Africa US Protective Coatings Market Revenue (undefined), by Country 2024 & 2032

- Figure 35: Middle East & Africa US Protective Coatings Market Revenue Share (%), by Country 2024 & 2032

- Figure 36: Asia Pacific US Protective Coatings Market Revenue (undefined), by Resin Type 2024 & 2032

- Figure 37: Asia Pacific US Protective Coatings Market Revenue Share (%), by Resin Type 2024 & 2032

- Figure 38: Asia Pacific US Protective Coatings Market Revenue (undefined), by Technology 2024 & 2032

- Figure 39: Asia Pacific US Protective Coatings Market Revenue Share (%), by Technology 2024 & 2032

- Figure 40: Asia Pacific US Protective Coatings Market Revenue (undefined), by End-user Industry 2024 & 2032

- Figure 41: Asia Pacific US Protective Coatings Market Revenue Share (%), by End-user Industry 2024 & 2032

- Figure 42: Asia Pacific US Protective Coatings Market Revenue (undefined), by Country 2024 & 2032

- Figure 43: Asia Pacific US Protective Coatings Market Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global US Protective Coatings Market Revenue undefined Forecast, by Region 2019 & 2032

- Table 2: Global US Protective Coatings Market Revenue undefined Forecast, by Resin Type 2019 & 2032

- Table 3: Global US Protective Coatings Market Revenue undefined Forecast, by Technology 2019 & 2032

- Table 4: Global US Protective Coatings Market Revenue undefined Forecast, by End-user Industry 2019 & 2032

- Table 5: Global US Protective Coatings Market Revenue undefined Forecast, by Region 2019 & 2032

- Table 6: Global US Protective Coatings Market Revenue undefined Forecast, by Country 2019 & 2032

- Table 7: Northeast US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 8: Southeast US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 9: Midwest US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 10: Southwest US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 11: West US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 12: Global US Protective Coatings Market Revenue undefined Forecast, by Resin Type 2019 & 2032

- Table 13: Global US Protective Coatings Market Revenue undefined Forecast, by Technology 2019 & 2032

- Table 14: Global US Protective Coatings Market Revenue undefined Forecast, by End-user Industry 2019 & 2032

- Table 15: Global US Protective Coatings Market Revenue undefined Forecast, by Country 2019 & 2032

- Table 16: United States US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 17: Canada US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 18: Mexico US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 19: Global US Protective Coatings Market Revenue undefined Forecast, by Resin Type 2019 & 2032

- Table 20: Global US Protective Coatings Market Revenue undefined Forecast, by Technology 2019 & 2032

- Table 21: Global US Protective Coatings Market Revenue undefined Forecast, by End-user Industry 2019 & 2032

- Table 22: Global US Protective Coatings Market Revenue undefined Forecast, by Country 2019 & 2032

- Table 23: Brazil US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 24: Argentina US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 25: Rest of South America US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 26: Global US Protective Coatings Market Revenue undefined Forecast, by Resin Type 2019 & 2032

- Table 27: Global US Protective Coatings Market Revenue undefined Forecast, by Technology 2019 & 2032

- Table 28: Global US Protective Coatings Market Revenue undefined Forecast, by End-user Industry 2019 & 2032

- Table 29: Global US Protective Coatings Market Revenue undefined Forecast, by Country 2019 & 2032

- Table 30: United Kingdom US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 31: Germany US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 32: France US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 33: Italy US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 34: Spain US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 35: Russia US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 36: Benelux US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 37: Nordics US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 38: Rest of Europe US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 39: Global US Protective Coatings Market Revenue undefined Forecast, by Resin Type 2019 & 2032

- Table 40: Global US Protective Coatings Market Revenue undefined Forecast, by Technology 2019 & 2032

- Table 41: Global US Protective Coatings Market Revenue undefined Forecast, by End-user Industry 2019 & 2032

- Table 42: Global US Protective Coatings Market Revenue undefined Forecast, by Country 2019 & 2032

- Table 43: Turkey US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 44: Israel US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 45: GCC US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 46: North Africa US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 47: South Africa US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 48: Rest of Middle East & Africa US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 49: Global US Protective Coatings Market Revenue undefined Forecast, by Resin Type 2019 & 2032

- Table 50: Global US Protective Coatings Market Revenue undefined Forecast, by Technology 2019 & 2032

- Table 51: Global US Protective Coatings Market Revenue undefined Forecast, by End-user Industry 2019 & 2032

- Table 52: Global US Protective Coatings Market Revenue undefined Forecast, by Country 2019 & 2032

- Table 53: China US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 54: India US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 55: Japan US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 56: South Korea US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 57: ASEAN US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 58: Oceania US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

- Table 59: Rest of Asia Pacific US Protective Coatings Market Revenue (undefined) Forecast, by Application 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the US Protective Coatings Market?

The projected CAGR is approximately 4.02%.

2. Which companies are prominent players in the US Protective Coatings Market?

Key companies in the market include AkzoNobel N V, Dampney, Jotun, INDURON, RPM International Inc, DECO Coatings, PPG Industries Inc, Beckers Group, APV Coatings, Axalta Coating Systems, Heresite, Hempel A/S, Tnemec, The Sherwin Williams Company, US Coatings*List Not Exhaustive, MIPA SE.

3. What are the main segments of the US Protective Coatings Market?

The market segments include Resin Type, Technology, End-user Industry.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

Increasing Activity in the Oil and Gas Sector; Infrastructure sector to Fuel in the Demand for Protective Coatings.

6. What are the notable trends driving market growth?

Increasing Activity in the Oil and Gas Sector.

7. Are there any restraints impacting market growth?

Price Hikes of Raw Materials; Other Restraints.

8. Can you provide examples of recent developments in the market?

January 2022: Seal for Life Industries, a paints and coatings manufacturer, acquired two privately owned industrial coatings companies based out of the United States, which include Mascoat Ltd and Verdia Inc.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "US Protective Coatings Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the US Protective Coatings Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the US Protective Coatings Market?

To stay informed about further developments, trends, and reports in the US Protective Coatings Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence