Key Insights

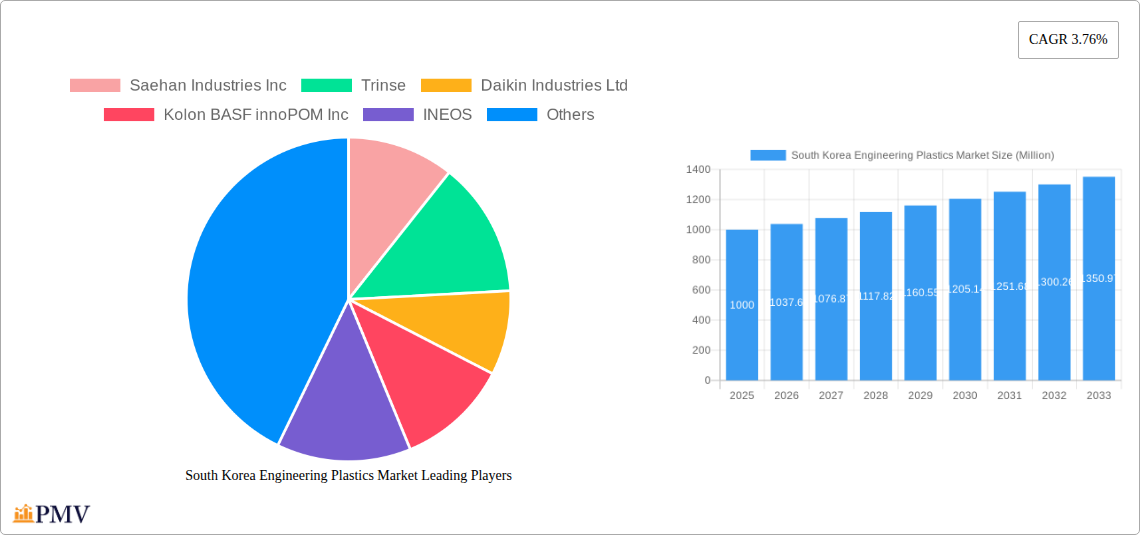

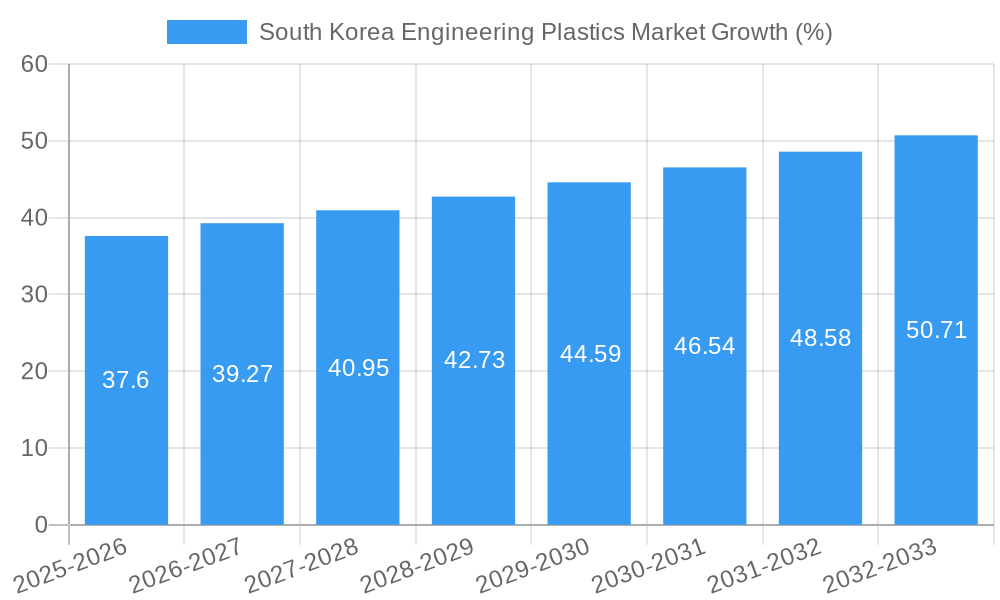

The South Korea engineering plastics market, valued at approximately $XX million in 2025, is projected to experience steady growth, exhibiting a compound annual growth rate (CAGR) of 3.76% from 2025 to 2033. This expansion is fueled by several key drivers. The robust automotive and electronics sectors in South Korea are significant consumers of engineering plastics, driving demand for high-performance materials in vehicles and consumer electronics. Furthermore, the construction industry's ongoing development and infrastructure projects contribute to increased demand for durable and lightweight materials. Growth in the aerospace sector, albeit smaller, also presents opportunities. The market is segmented by resin type (Fluoropolymer, Polyphthalamide, PBT, PC, PEEK, PET, PI, PMMA, POM, ABS/SAN) and end-user industries (Aerospace, Automotive, Building & Construction, Electrical & Electronics, Industrial & Machinery, Packaging). Competitive dynamics are shaped by both global players like BASF SE, Ineos, and Mitsubishi Chemical Corporation, and domestic companies such as LG Chem, Samyang Corporation, and Kolon Industries Inc., indicating a blend of international expertise and local market knowledge.

However, certain restraints might temper growth. Fluctuations in raw material prices, particularly for petroleum-based plastics, could impact profitability and potentially lead to price increases. Furthermore, increasing environmental concerns and the growing adoption of sustainable alternatives might necessitate adaptation and innovation within the industry. To maintain competitiveness, manufacturers are likely to focus on developing advanced materials with enhanced properties like improved strength-to-weight ratios, better thermal resistance, and enhanced recyclability. The market’s future trajectory will depend on the continued expansion of key end-use sectors, technological advancements in material science, and the industry's ability to address sustainability concerns effectively. The forecast period anticipates a steady, albeit moderate, expansion based on the existing growth trajectory and projected developments in the South Korean economy.

This comprehensive report provides an in-depth analysis of the South Korea engineering plastics market, covering market size, growth drivers, competitive landscape, and future outlook. The study period spans from 2019 to 2033, with 2025 serving as the base and estimated year. The report offers actionable insights for industry stakeholders, including manufacturers, suppliers, distributors, and investors. With a focus on key trends and future projections, this report is an essential resource for navigating the dynamic South Korea engineering plastics market. The market is valued at xx Million in 2025 and is projected to reach xx Million by 2033, exhibiting a CAGR of xx% during the forecast period (2025-2033).

South Korea Engineering Plastics Market Market Structure & Competitive Dynamics

The South Korean engineering plastics market exhibits a moderately concentrated structure, with several multinational and domestic players vying for market share. Key players include Saehan Industries Inc, Trinse, Daikin Industries Ltd, Kolon BASF innoPOM Inc, INEOS, Mitsubishi Chemical Corporation, SK chemicals, Lotte Chemical, Korea Engineering Plastics Co Ltd, BASF SE, LG Chem, Samyang Corporation, Kumho Petrochemical, Kolon Industries Inc, and LX MMA. Market share distribution is dynamic, influenced by factors such as innovation, pricing strategies, and customer relationships.

The market's innovation ecosystem is robust, driven by ongoing R&D efforts focused on sustainable materials and enhanced performance characteristics. Stringent regulatory frameworks, particularly concerning environmental regulations and product safety, shape the competitive landscape. The presence of substitute materials, such as bioplastics and metal alloys, presents a competitive challenge. End-user trends towards lightweighting, durability, and sustainability are influencing material choices. M&A activities have been relatively moderate in recent years, with deal values ranging from xx Million to xx Million. However, strategic partnerships and joint ventures are common, reflecting the collaborative nature of the industry.

- Market Concentration: Moderately concentrated

- Innovation Ecosystem: Robust, focused on sustainability and performance

- Regulatory Framework: Stringent, impacting material choices and manufacturing processes

- Product Substitutes: Bioplastics and metal alloys

- End-User Trends: Lightweighting, durability, and sustainability

South Korea Engineering Plastics Market Industry Trends & Insights

The South Korea engineering plastics market is characterized by steady growth, driven by increasing demand across diverse end-use sectors. The automotive industry remains a dominant driver, fueled by the increasing adoption of lightweight materials to improve fuel efficiency and reduce vehicle emissions. The electrical and electronics sector is another key contributor, as engineering plastics are crucial in manufacturing electronic devices and components. The construction industry’s demand is growing due to the rising use of plastics in infrastructure development. Technological advancements are shaping market dynamics, with a strong emphasis on developing high-performance, sustainable, and cost-effective materials. Consumer preferences for environmentally friendly products are driving innovation in bio-based engineering plastics. The competitive landscape is marked by both domestic and international players, leading to intense competition based on price, quality, and innovation. The market experienced a CAGR of xx% between 2019 and 2024 and is projected to maintain a healthy growth trajectory in the coming years. Market penetration of specific engineering plastics varies by end-use sector. For instance, PBT and PC have high penetration in the automotive sector, while fluoropolymers dominate in specific niche applications within aerospace.

Dominant Markets & Segments in South Korea Engineering Plastics Market

The automotive industry is the dominant end-user segment in the South Korea engineering plastics market, accounting for xx% of total consumption in 2025. This is driven by the increasing production of vehicles, the growing demand for lightweight and fuel-efficient vehicles, and the rising adoption of advanced driver-assistance systems (ADAS). The electrical and electronics sector is another significant segment, with a market share of xx%, fueled by the rising demand for electronic devices and the growing adoption of 5G technology. The building and construction industry is also a significant market, with increasing applications of plastics in infrastructure and construction materials.

Key Drivers of Dominant Segments:

- Automotive: Growing vehicle production, demand for lightweight vehicles, ADAS adoption.

- Electrical & Electronics: Rising demand for electronic devices, 5G adoption, miniaturization trends.

- Building & Construction: Infrastructure development, use of plastics in construction materials.

Among resin types, Polybutylene Terephthalate (PBT) and Polycarbonate (PC) hold significant market share due to their versatility and high performance. Other notable segments include POM, ABS, and fluoropolymers, each with specific niche applications and growth prospects.

South Korea Engineering Plastics Market Product Innovations

Recent years have witnessed significant advancements in engineering plastics, focusing on enhanced sustainability and improved performance. Manufacturers are actively developing bio-based alternatives and incorporating recycled content to meet growing environmental concerns. Innovations include the introduction of low-carbon footprint POM materials (as exemplified by BASF's Ultraform LowPCF and Ultraform BMB) and high-performance specialty ABS products (as exemplified by INEOS' Novodur E3TZ). These developments aim to improve sustainability profiles while maintaining or improving material performance. The focus is on tailoring materials to specific end-user applications, leading to highly specialized products optimized for performance, durability, and cost-effectiveness.

Report Segmentation & Scope

This report segments the South Korea engineering plastics market by resin type and end-user industry.

Resin Type: Fluoropolymer, Polyphthalamide, Polybutylene Terephthalate (PBT), Polycarbonate (PC), Polyether Ether Ketone (PEEK), Polyethylene Terephthalate (PET), Polyimide (PI), Polymethyl Methacrylate (PMMA), Polyoxymethylene (POM), Styrene Copolymers (ABS and SAN). Each segment's growth projections, market sizes, and competitive dynamics are analyzed in detail, considering factors like material properties, cost-effectiveness, and application suitability.

End-User Industry: Aerospace, Automotive, Building and Construction, Electrical and Electronics, Industrial and Machinery, Packaging, Other End-user Industries. The report assesses the market share and growth potential of engineering plastics within each end-use sector, considering specific industry trends and technological advancements.

Key Drivers of South Korea Engineering Plastics Market Growth

The South Korea engineering plastics market's growth is propelled by several key drivers. Firstly, the robust automotive industry, with its focus on lightweighting and fuel efficiency, drives significant demand for engineering plastics. Secondly, the expanding electronics and electrical sectors fuel demand for high-performance materials in consumer electronics and infrastructure projects. Thirdly, ongoing government support for infrastructure development and investments in sustainable technologies create a favourable environment for market expansion. Finally, the increasing emphasis on sustainability and circular economy principles fosters innovation in bio-based and recycled engineering plastics.

Challenges in the South Korea Engineering Plastics Market Sector

The South Korea engineering plastics market faces several challenges. Fluctuations in raw material prices and supply chain disruptions impact profitability and production stability. Intense competition from both domestic and international players necessitates continuous innovation and cost optimization. Stringent environmental regulations and the increasing demand for sustainable materials necessitate significant investment in R&D and sustainable manufacturing practices. Furthermore, adapting to rapid technological changes in end-use applications requires consistent product development and market adaptation.

Leading Players in the South Korea Engineering Plastics Market Market

- Saehan Industries Inc

- Trinse

- Daikin Industries Ltd

- Kolon BASF innoPOM Inc

- INEOS

- Mitsubishi Chemical Corporation

- SK chemicals

- Lotte Chemical

- Korea Engineering Plastics Co Ltd

- BASF SE

- LG Chem

- Samyang Corporation

- Kumho Petrochemical

- Kolon Industries Inc

- LX MMA

Key Developments in South Korea Engineering Plastics Market Sector

- August 2022: INEOS launched a comprehensive range of sustainable ABS solutions (Novodur), boasting up to a 71% reduction in product carbon footprint.

- August 2022: INEOS introduced Novodur E3TZ, a high-performance extrusion-grade ABS for applications like food trays and suitcases.

- October 2022: BASF introduced Ultraform LowPCF and Ultraform BMB, sustainable POM products reducing carbon footprint and GHG emissions.

Strategic South Korea Engineering Plastics Market Outlook

The South Korea engineering plastics market exhibits strong growth potential, driven by sustained growth in key end-use sectors, ongoing technological advancements, and a growing emphasis on sustainability. Strategic opportunities exist in developing innovative, high-performance, and sustainable materials tailored to specific applications. Companies focusing on R&D, partnerships, and environmentally conscious manufacturing processes are well-positioned to capture significant market share in the coming years. Expanding into niche applications and leveraging digital technologies for efficient manufacturing and supply chain management will be crucial for success.

South Korea Engineering Plastics Market Segmentation

-

1. End User Industry

- 1.1. Aerospace

- 1.2. Automotive

- 1.3. Building and Construction

- 1.4. Electrical and Electronics

- 1.5. Industrial and Machinery

- 1.6. Packaging

- 1.7. Other End-user Industries

-

2. Resin Type

-

2.1. Fluoropolymer

-

2.1.1. By Sub Resin Type

- 2.1.1.1. Ethylenetetrafluoroethylene (ETFE)

- 2.1.1.2. Fluorinated Ethylene-propylene (FEP)

- 2.1.1.3. Polytetrafluoroethylene (PTFE)

- 2.1.1.4. Polyvinylfluoride (PVF)

- 2.1.1.5. Polyvinylidene Fluoride (PVDF)

- 2.1.1.6. Other Sub Resin Types

-

2.1.1. By Sub Resin Type

- 2.2. Liquid Crystal Polymer (LCP)

-

2.3. Polyamide (PA)

- 2.3.1. Aramid

- 2.3.2. Polyamide (PA) 6

- 2.3.3. Polyamide (PA) 66

- 2.3.4. Polyphthalamide

- 2.4. Polybutylene Terephthalate (PBT)

- 2.5. Polycarbonate (PC)

- 2.6. Polyether Ether Ketone (PEEK)

- 2.7. Polyethylene Terephthalate (PET)

- 2.8. Polyimide (PI)

- 2.9. Polymethyl Methacrylate (PMMA)

- 2.10. Polyoxymethylene (POM)

- 2.11. Styrene Copolymers (ABS and SAN)

-

2.1. Fluoropolymer

South Korea Engineering Plastics Market Segmentation By Geography

- 1. South Korea

South Korea Engineering Plastics Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 3.76% from 2019-2033 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. Increased Demand for Architectural Coatings; Increasing Demand for Rheology Modifiers in Various Industries; Other Drivers

- 3.3. Market Restrains

- 3.3.1. Rising Environmental Regulations; Other Restraints

- 3.4. Market Trends

- 3.4.1. OTHER KEY INDUSTRY TRENDS COVERED IN THE REPORT

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. South Korea Engineering Plastics Market Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by End User Industry

- 5.1.1. Aerospace

- 5.1.2. Automotive

- 5.1.3. Building and Construction

- 5.1.4. Electrical and Electronics

- 5.1.5. Industrial and Machinery

- 5.1.6. Packaging

- 5.1.7. Other End-user Industries

- 5.2. Market Analysis, Insights and Forecast - by Resin Type

- 5.2.1. Fluoropolymer

- 5.2.1.1. By Sub Resin Type

- 5.2.1.1.1. Ethylenetetrafluoroethylene (ETFE)

- 5.2.1.1.2. Fluorinated Ethylene-propylene (FEP)

- 5.2.1.1.3. Polytetrafluoroethylene (PTFE)

- 5.2.1.1.4. Polyvinylfluoride (PVF)

- 5.2.1.1.5. Polyvinylidene Fluoride (PVDF)

- 5.2.1.1.6. Other Sub Resin Types

- 5.2.1.1. By Sub Resin Type

- 5.2.2. Liquid Crystal Polymer (LCP)

- 5.2.3. Polyamide (PA)

- 5.2.3.1. Aramid

- 5.2.3.2. Polyamide (PA) 6

- 5.2.3.3. Polyamide (PA) 66

- 5.2.3.4. Polyphthalamide

- 5.2.4. Polybutylene Terephthalate (PBT)

- 5.2.5. Polycarbonate (PC)

- 5.2.6. Polyether Ether Ketone (PEEK)

- 5.2.7. Polyethylene Terephthalate (PET)

- 5.2.8. Polyimide (PI)

- 5.2.9. Polymethyl Methacrylate (PMMA)

- 5.2.10. Polyoxymethylene (POM)

- 5.2.11. Styrene Copolymers (ABS and SAN)

- 5.2.1. Fluoropolymer

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. South Korea

- 5.1. Market Analysis, Insights and Forecast - by End User Industry

- 6. Competitive Analysis

- 6.1. Market Share Analysis 2024

- 6.2. Company Profiles

- 6.2.1 Saehan Industries Inc

- 6.2.1.1. Overview

- 6.2.1.2. Products

- 6.2.1.3. SWOT Analysis

- 6.2.1.4. Recent Developments

- 6.2.1.5. Financials (Based on Availability)

- 6.2.2 Trinse

- 6.2.2.1. Overview

- 6.2.2.2. Products

- 6.2.2.3. SWOT Analysis

- 6.2.2.4. Recent Developments

- 6.2.2.5. Financials (Based on Availability)

- 6.2.3 Daikin Industries Ltd

- 6.2.3.1. Overview

- 6.2.3.2. Products

- 6.2.3.3. SWOT Analysis

- 6.2.3.4. Recent Developments

- 6.2.3.5. Financials (Based on Availability)

- 6.2.4 Kolon BASF innoPOM Inc

- 6.2.4.1. Overview

- 6.2.4.2. Products

- 6.2.4.3. SWOT Analysis

- 6.2.4.4. Recent Developments

- 6.2.4.5. Financials (Based on Availability)

- 6.2.5 INEOS

- 6.2.5.1. Overview

- 6.2.5.2. Products

- 6.2.5.3. SWOT Analysis

- 6.2.5.4. Recent Developments

- 6.2.5.5. Financials (Based on Availability)

- 6.2.6 Mitsubishi Chemical Corporation

- 6.2.6.1. Overview

- 6.2.6.2. Products

- 6.2.6.3. SWOT Analysis

- 6.2.6.4. Recent Developments

- 6.2.6.5. Financials (Based on Availability)

- 6.2.7 SK chemicals

- 6.2.7.1. Overview

- 6.2.7.2. Products

- 6.2.7.3. SWOT Analysis

- 6.2.7.4. Recent Developments

- 6.2.7.5. Financials (Based on Availability)

- 6.2.8 Lotte Chemical

- 6.2.8.1. Overview

- 6.2.8.2. Products

- 6.2.8.3. SWOT Analysis

- 6.2.8.4. Recent Developments

- 6.2.8.5. Financials (Based on Availability)

- 6.2.9 Korea Engineering Plastics Co Ltd

- 6.2.9.1. Overview

- 6.2.9.2. Products

- 6.2.9.3. SWOT Analysis

- 6.2.9.4. Recent Developments

- 6.2.9.5. Financials (Based on Availability)

- 6.2.10 BASF SE

- 6.2.10.1. Overview

- 6.2.10.2. Products

- 6.2.10.3. SWOT Analysis

- 6.2.10.4. Recent Developments

- 6.2.10.5. Financials (Based on Availability)

- 6.2.11 LG Chem

- 6.2.11.1. Overview

- 6.2.11.2. Products

- 6.2.11.3. SWOT Analysis

- 6.2.11.4. Recent Developments

- 6.2.11.5. Financials (Based on Availability)

- 6.2.12 Samyang Corporation

- 6.2.12.1. Overview

- 6.2.12.2. Products

- 6.2.12.3. SWOT Analysis

- 6.2.12.4. Recent Developments

- 6.2.12.5. Financials (Based on Availability)

- 6.2.13 Kumho Petrochemical

- 6.2.13.1. Overview

- 6.2.13.2. Products

- 6.2.13.3. SWOT Analysis

- 6.2.13.4. Recent Developments

- 6.2.13.5. Financials (Based on Availability)

- 6.2.14 Kolon Industries Inc

- 6.2.14.1. Overview

- 6.2.14.2. Products

- 6.2.14.3. SWOT Analysis

- 6.2.14.4. Recent Developments

- 6.2.14.5. Financials (Based on Availability)

- 6.2.15 LX MMA

- 6.2.15.1. Overview

- 6.2.15.2. Products

- 6.2.15.3. SWOT Analysis

- 6.2.15.4. Recent Developments

- 6.2.15.5. Financials (Based on Availability)

- 6.2.1 Saehan Industries Inc

List of Figures

- Figure 1: South Korea Engineering Plastics Market Revenue Breakdown (Million, %) by Product 2024 & 2032

- Figure 2: South Korea Engineering Plastics Market Share (%) by Company 2024

List of Tables

- Table 1: South Korea Engineering Plastics Market Revenue Million Forecast, by Region 2019 & 2032

- Table 2: South Korea Engineering Plastics Market Revenue Million Forecast, by End User Industry 2019 & 2032

- Table 3: South Korea Engineering Plastics Market Revenue Million Forecast, by Resin Type 2019 & 2032

- Table 4: South Korea Engineering Plastics Market Revenue Million Forecast, by Region 2019 & 2032

- Table 5: South Korea Engineering Plastics Market Revenue Million Forecast, by Country 2019 & 2032

- Table 6: South Korea Engineering Plastics Market Revenue Million Forecast, by End User Industry 2019 & 2032

- Table 7: South Korea Engineering Plastics Market Revenue Million Forecast, by Resin Type 2019 & 2032

- Table 8: South Korea Engineering Plastics Market Revenue Million Forecast, by Country 2019 & 2032

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the South Korea Engineering Plastics Market?

The projected CAGR is approximately 3.76%.

2. Which companies are prominent players in the South Korea Engineering Plastics Market?

Key companies in the market include Saehan Industries Inc, Trinse, Daikin Industries Ltd, Kolon BASF innoPOM Inc, INEOS, Mitsubishi Chemical Corporation, SK chemicals, Lotte Chemical, Korea Engineering Plastics Co Ltd, BASF SE, LG Chem, Samyang Corporation, Kumho Petrochemical, Kolon Industries Inc, LX MMA.

3. What are the main segments of the South Korea Engineering Plastics Market?

The market segments include End User Industry, Resin Type.

4. Can you provide details about the market size?

The market size is estimated to be USD XX Million as of 2022.

5. What are some drivers contributing to market growth?

Increased Demand for Architectural Coatings; Increasing Demand for Rheology Modifiers in Various Industries; Other Drivers.

6. What are the notable trends driving market growth?

OTHER KEY INDUSTRY TRENDS COVERED IN THE REPORT.

7. Are there any restraints impacting market growth?

Rising Environmental Regulations; Other Restraints.

8. Can you provide examples of recent developments in the market?

October 2022: BASF SE introduced two new sustainable POM products, Ultraform LowPCF (Low Product Carbon Footprint) and Ultraform BMB (Biomass Balance), to reduce the carbon footprint, save fossil resources, and support the reduction of greenhouse gas (GHG) emissions.August 2022: INEOS announced the introduction of an extension to its high-performance Novodur line of specialty ABS products. The new Novodur E3TZ is an extrusion grade that is suitable for a variety of applications, including food trays, sanitary applications, and suitcases.August 2022: INEOS announced the introduction of a comprehensive range of sustainable solutions for its specialty ABS product group Novodur addressing applications in a range of industries, including automotive, electronics, and household. The individual grades come with a significant product carbon footprint (PCF) saving of up to -71% as compared to the respective non-ECO product reference.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 3800, USD 4500, and USD 5800 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "South Korea Engineering Plastics Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the South Korea Engineering Plastics Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the South Korea Engineering Plastics Market?

To stay informed about further developments, trends, and reports in the South Korea Engineering Plastics Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence