Key Insights

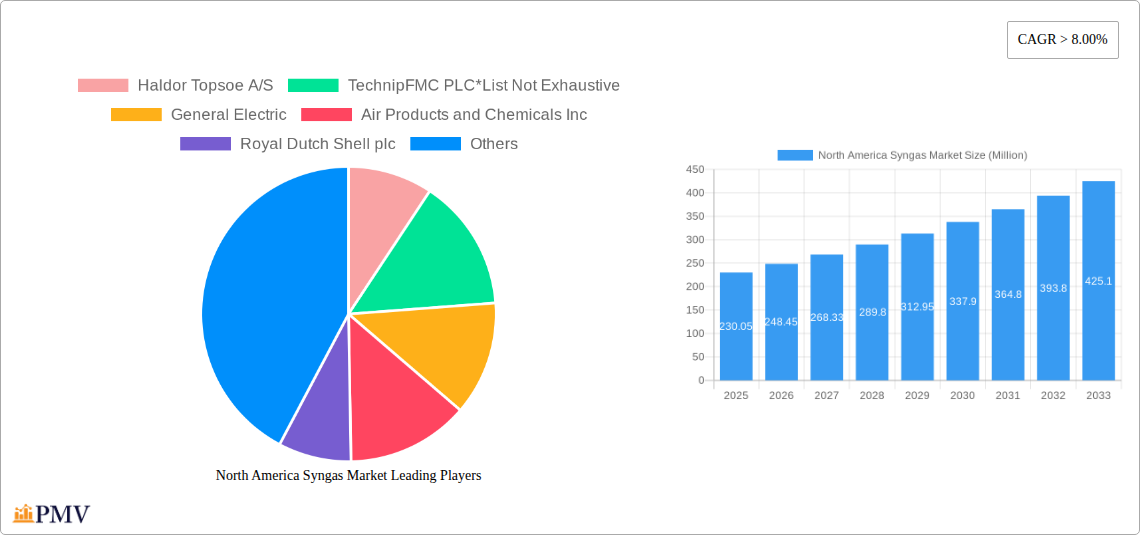

The North American Syngas Market is poised for substantial growth, projected to reach a valuation of approximately USD 230.05 million. This robust expansion is fueled by a Compound Annual Growth Rate (CAGR) exceeding 8.00%, indicating a dynamic and expanding industry. A primary driver for this growth is the increasing demand for cleaner energy sources and industrial feedstocks. The transition towards more sustainable energy solutions necessitates advanced gasification and reforming technologies, which syngas production is central to. Furthermore, the burgeoning chemical industry, particularly the demand for methanol, ammonia, and oxo chemicals, acts as a significant growth catalyst. The versatility of syngas as a fundamental building block for a wide array of industrial applications, from power generation to the synthesis of liquid and gaseous fuels, underpins its market dominance. Key technologies such as steam reforming and partial oxidation are expected to see increased adoption, alongside advancements in biomass gasification, reflecting a concerted effort towards diversifying feedstock sources and enhancing operational efficiency.

North America Syngas Market Market Size (In Million)

The market's trajectory is further shaped by strategic investments in infrastructure and the continuous development of more efficient and environmentally friendly syngas production methods. Emerging trends include the focus on carbon capture utilization and storage (CCUS) integration within syngas facilities to mitigate environmental impact and enhance the economic viability of the process. The growing emphasis on hydrogen as a clean fuel is also a significant contributor, as syngas is a primary source for its production. While the market enjoys strong growth, certain restraints, such as the capital-intensive nature of syngas plants and fluctuating feedstock prices, need to be carefully managed. However, the overarching trend towards decarbonization and the need for diversified industrial processes position the North American syngas market for sustained and significant expansion throughout the forecast period. The dominance of coal and natural gas as feedstocks is likely to continue in the near term, but the increasing prominence of biomass and pet-coke reflects a strategic shift towards more sustainable and readily available resources.

North America Syngas Market Company Market Share

North America Syngas Market Detailed Report Description

This comprehensive report delves into the dynamic North America Syngas Market, offering an in-depth analysis of its structure, trends, competitive landscape, and future outlook. Covering the historical period of 2019-2024 and projecting growth through 2033, with a base year of 2025, this report provides actionable insights for stakeholders seeking to capitalize on this expanding energy and chemical feedstock market. Key segments explored include feedstock types (Coal, Natural Gas, Petroleum, Pet-coke, Biomass), advanced technologies (Steam Reforming, Partial Oxidation, Auto-thermal Reforming, Combined or Two-step Reforming, Biomass Gasification), diverse gasifier types (Fixed Bed, Entrained Flow, Fluidized Bed), critical applications (Power Generation, Chemicals such as Methanol, Ammonia, Oxo Chemicals, n-Butanol, Hydrogen, Dimethyl Ether, Liquid Fuels, Gaseous Fuels), and detailed geographical breakdowns across the United States, Canada, Mexico, and the Rest of North America.

North America Syngas Market Market Structure & Competitive Dynamics

The North America Syngas Market is characterized by a moderately concentrated structure, with major players like Linde plc, Air Products and Chemicals Inc., and Siemens holding significant market shares. Innovation thrives through ongoing R&D investments in more efficient and environmentally friendly gasification technologies, particularly for biomass and cleaner coal utilization. The regulatory framework, while evolving, often supports the transition to cleaner energy sources and the utilization of syngas for chemical production. Product substitutes exist, primarily in the form of direct fossil fuel combustion for power, but the increasing demand for cleaner alternatives and higher value chemical intermediates positions syngas favorably. End-user trends are shifting towards sustainable chemical production and integrated gasification combined cycle (IGCC) power plants. Mergers and acquisitions (M&A) activities, though not at peak levels, are strategic, focusing on technology acquisition and market expansion. Estimated M&A deal values are projected to see moderate growth in the coming years as companies seek to consolidate their positions and diversify their syngas portfolios.

- Market Concentration: Moderate, driven by established players and technological expertise.

- Innovation Ecosystem: Robust R&D in gasification, carbon capture, and catalyst development.

- Regulatory Framework: Supportive policies for clean energy and industrial decarbonization.

- Product Substitutes: Direct combustion of fossil fuels, renewable energy sources.

- End-User Trends: Growing demand for green chemicals, industrial decarbonization solutions.

- M&A Activities: Strategic acquisitions for technology, market access, and vertical integration.

North America Syngas Market Industry Trends & Insights

The North America Syngas Market is poised for substantial growth, driven by several converging factors. The increasing global demand for cleaner energy alternatives and the imperative for industrial decarbonization are primary growth catalysts. Syngas, as a versatile intermediate, plays a crucial role in the production of a wide array of chemicals, including methanol, ammonia, and hydrogen, which are essential for various downstream industries like agriculture, manufacturing, and energy. Furthermore, the growing interest in producing liquid and gaseous fuels from non-fossil sources, such as biomass and waste, is significantly boosting the market. Technological advancements in gasification processes are enhancing efficiency, reducing emissions, and lowering operational costs, making syngas production more economically viable.

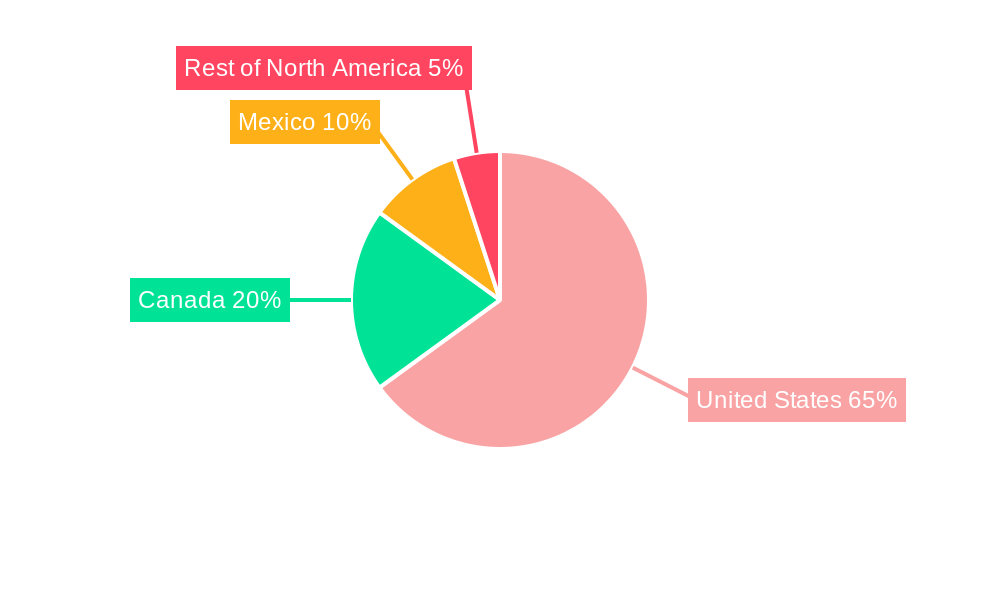

The United States is expected to dominate the North American syngas market due to its large industrial base, significant natural gas reserves, and ongoing investments in advanced gasification technologies and carbon capture and storage (CCS) initiatives. The Chemicals application segment, particularly for Methanol, Ammonia, and Hydrogen production, is anticipated to witness the highest growth rate, driven by their indispensable roles in various industrial processes and the burgeoning hydrogen economy. Natural Gas remains the dominant feedstock, owing to its availability and relatively lower cost compared to coal, although the use of Biomass is gaining traction as a sustainable alternative.

The Steam Reforming technology is expected to maintain its leadership position due to its established efficiency and widespread application, particularly for natural gas. However, advancements in Biomass Gasification are making it a more competitive and environmentally attractive option. The forecast period (2025-2033) is projected to see a Compound Annual Growth Rate (CAGR) of approximately 5.5%, with the market size reaching an estimated $45,000 Million by 2033. Market penetration of syngas-derived products is expected to increase significantly as industries pivot towards sustainable feedstock and cleaner production methods. The integration of syngas technologies with renewable energy sources and waste-to-energy solutions will further propel market expansion.

Dominant Markets & Segments in North America Syngas Market

The North America Syngas Market is significantly influenced by its key segments and geographical concentrations.

Geography Dominance:

- United States: This nation is projected to maintain its stronghold on the North America syngas market. Its dominance is attributed to a robust industrial sector, abundant natural gas reserves, and proactive government initiatives supporting clean energy transitions and the development of advanced chemical manufacturing. Significant investments in research and development for syngas technologies, including carbon capture, further solidify its leading position. The presence of major chemical and petrochemical hubs also drives demand for syngas-derived products.

- Canada: Canada represents a substantial market share, primarily driven by its extensive oil sands operations which generate pet-coke, a viable feedstock for syngas production. Its burgeoning renewable energy sector and increasing focus on developing hydrogen as a clean fuel also contribute to market growth.

- Mexico: While a smaller player, Mexico's industrial growth and its efforts to modernize its energy infrastructure present opportunities for syngas adoption, particularly for chemical production.

Feedstock Dominance:

- Natural Gas: Continues to be the dominant feedstock due to its wide availability, established infrastructure, and cost-effectiveness in North America. Its use in steam reforming and auto-thermal reforming processes makes it a cornerstone of current syngas production.

- Coal: Remains a significant feedstock, especially in regions with large coal reserves and established gasification facilities. However, its market share is expected to see a relative decline due to environmental concerns and a global shift towards cleaner energy sources.

- Biomass: This segment is experiencing the fastest growth. Driven by sustainability mandates and the desire to reduce reliance on fossil fuels, biomass gasification is gaining traction for its potential to produce 'green' syngas for chemicals and fuels.

- Pet-coke: Primarily utilized in regions with significant petroleum refining activities, contributing to syngas production for internal use or specialized applications.

Technology Dominance:

- Steam Reforming: Remains the most widely adopted technology, especially for natural gas, due to its high efficiency and established track record in producing hydrogen and carbon monoxide.

- Partial Oxidation (POX) & Auto-thermal Reforming (ATR): These technologies are crucial for gasifying heavier hydrocarbons and are widely employed in refineries and industrial settings.

- Biomass Gasification: This technology is witnessing significant innovation and investment, driven by the growing demand for renewable syngas. Improvements in gasifier design and efficiency are making it increasingly competitive.

Gasifier Type Dominance:

- Entrained Flow Gasifiers: Dominant for large-scale industrial applications, particularly with coal and pet-coke, due to their high throughput and efficiency.

- Fluidized Bed Gasifiers: Gaining prominence, especially for biomass and waste feedstocks, due to their ability to handle diverse materials and operate at lower temperatures, reducing tar formation.

Application Dominance:

- Chemicals: This is the most significant application segment, with Methanol, Ammonia, and Hydrogen production consuming the largest volumes of syngas. The growing demand for these chemicals in fertilizers, plastics, and the burgeoning hydrogen economy fuels this segment's growth.

- Power Generation: Integrated Gasification Combined Cycle (IGCC) plants, while capital-intensive, offer a cleaner method of generating electricity from coal and other feedstocks, contributing to this application's importance.

- Liquid Fuels & Gaseous Fuels: The production of synthetic fuels (e.g., Fischer-Tropsch) and the blending of syngas into natural gas grids represent growing opportunities, particularly with the focus on energy independence and cleaner fuel alternatives.

North America Syngas Market Product Innovations

Product innovations in the North America Syngas Market are primarily focused on enhancing efficiency, reducing environmental impact, and expanding feedstock versatility. Companies are developing advanced gasifier designs that can process a wider range of feedstocks, including challenging materials like municipal solid waste and agricultural residues, with increased yields and lower emissions. Innovations in catalysts are crucial for optimizing syngas composition for specific downstream applications, such as the direct synthesis of higher alcohols or the improved production of hydrogen. The integration of carbon capture, utilization, and storage (CCUS) technologies with syngas production facilities is a major trend, aiming to achieve near-zero emissions and create valuable carbon-based products. These advancements are enhancing the competitiveness and sustainability of syngas production, making it a more attractive option for both energy and chemical sectors.

Report Segmentation & Scope

This report comprehensively segments the North America Syngas Market to provide a granular understanding of its dynamics. The analysis covers:

- Feedstock: Coal, Natural Gas, Petroleum, Pet-coke, and Biomass. This segmentation examines the market dynamics, cost structures, and environmental considerations associated with each feedstock.

- Technology: Steam Reforming, Partial Oxidation, Auto-thermal Reforming, Combined or Two-step Reforming, and Biomass Gasification. This segment details the adoption rates, technological maturity, and future potential of various gasification processes.

- Gasifier Type: Fixed Bed, Entrained Flow, and Fluidized Bed. This provides insights into the prevalent gasifier technologies used across different applications and feedstocks.

- Application: Power Generation, Chemicals (Methanol, Ammonia, Oxo Chemicals, n-Butanol, Hydrogen, Dimethyl Ether), Liquid Fuels, and Gaseous Fuels. This segment highlights the market size and growth prospects for syngas utilization in diverse end-use industries.

- Geography: United States, Canada, Mexico, and Rest of North America. This geographical breakdown offers detailed market analysis, including regional drivers, regulations, and competitive landscapes.

Each segment is analyzed for its current market size, projected growth rates, and key competitive dynamics, offering a complete view of the market's structure and future trajectory.

Key Drivers of North America Syngas Market Growth

The North America Syngas Market is propelled by a confluence of powerful drivers:

- Growing Demand for Sustainable Chemicals: The global push for greener manufacturing processes is increasing the demand for syngas as a feedstock for producing essential chemicals like methanol, ammonia, and hydrogen with a lower carbon footprint.

- Energy Transition and Decarbonization Efforts: Syngas plays a pivotal role in the energy transition, enabling cleaner power generation through IGCC plants and serving as a bridge fuel. Government policies and corporate sustainability goals are accelerating its adoption.

- Advancements in Gasification Technologies: Continuous R&D is leading to more efficient, cost-effective, and environmentally friendly gasification processes, including those for biomass and waste materials.

- Hydrogen Economy Development: The emerging hydrogen economy, driven by its potential as a clean fuel for transportation and industry, is a significant growth driver, as syngas is a primary precursor for hydrogen production.

- Energy Security and Diversification: The ability of syngas production to utilize diverse feedstocks, including domestic resources like natural gas and biomass, enhances energy security and reduces reliance on volatile global fossil fuel markets.

Challenges in the North America Syngas Market Sector

Despite its promising growth, the North America Syngas Market faces several challenges:

- High Capital Investment: Establishing syngas production facilities, particularly IGCC plants, requires substantial upfront capital investment, which can be a barrier for new entrants and smaller companies.

- Feedstock Availability and Price Volatility: While natural gas is abundant, its price can fluctuate. Securing a consistent and cost-effective supply of alternative feedstocks like biomass can also be challenging.

- Environmental Concerns and Regulations: Although syngas offers cleaner alternatives, the production process itself can have environmental implications, especially when using coal. Stringent regulations regarding emissions and waste disposal can increase operational costs.

- Technological Maturity and Efficiency: While advancements are ongoing, further improvements are needed in the efficiency and reliability of certain gasification technologies, particularly for complex feedstocks, to enhance their economic viability.

- Competition from Mature Technologies: Syngas competes with established and often cheaper methods of energy generation and chemical production, requiring a clear demonstration of its long-term cost and environmental advantages to gain wider adoption.

Leading Players in the North America Syngas Market Market

- Haldor Topsoe A/S

- TechnipFMC PLC

- General Electric

- Air Products and Chemicals Inc

- Royal Dutch Shell plc

- Siemens

- KBR Inc

- BASF SE

- Sasol

- Linde plc

- SynGas Technology LLC

- Air Liquide

- BP p l c

- Dakota Gasification Company Inc

Key Developments in North America Syngas Market Sector

- Investments in carbon capture and storage technologies: Ongoing significant investments are being made to integrate CCUS with syngas production facilities, aiming to achieve near-zero emissions and create carbon-neutral or carbon-negative processes. For example, numerous pilot projects have been announced and are progressing towards commercialization.

- Partnerships and collaborations between industry players: Strategic alliances are forming to leverage expertise, share risks, and accelerate the deployment of syngas technologies. These collaborations span technology developers, feedstock suppliers, and end-users.

- Expansion of biomass-based syngas production facilities: There is a notable surge in the development and expansion of facilities utilizing biomass feedstocks for syngas production, driven by the demand for renewable chemicals and fuels. Several new plants are slated for operation in the coming years, with a focus on agricultural residues and forestry waste.

Strategic North America Syngas Market Market Outlook

The strategic outlook for the North America Syngas Market is highly positive, driven by the twin imperatives of decarbonization and the growing demand for sustainable chemical feedstocks. Future growth will be significantly shaped by continued innovation in biomass gasification and the successful integration of carbon capture technologies, paving the way for truly green syngas production. The expanding hydrogen economy presents a substantial opportunity, as syngas is a critical precursor for blue and green hydrogen. Strategic investments in advanced gasifier designs and catalysts will unlock the potential of a wider range of feedstocks, enhancing market resilience and diversification. Furthermore, policy support for clean energy and chemical manufacturing will continue to foster a favorable investment climate, positioning the North America Syngas Market as a vital component of the region's future industrial and energy landscape.

North America Syngas Market Segmentation

-

1. Feedstock

- 1.1. Coal

- 1.2. Natural Gas

- 1.3. Petroleum

- 1.4. Pet-coke

- 1.5. Biomass

-

2. Technology

- 2.1. Steam Reforming

- 2.2. Partial Oxidation

- 2.3. Auto-thermal Reforming

- 2.4. Combined or Two-step Reforming

- 2.5. Biomass Gasification

-

3. Gasifier Type

- 3.1. Fixed Bed

- 3.2. Entrained Flow

- 3.3. Fluidized Bed

-

4. Application

- 4.1. Power Generation

-

4.2. Chemicals

- 4.2.1. Methanol

- 4.2.2. Ammonia

- 4.2.3. Oxo Chemicals

- 4.2.4. n-Butanol

- 4.2.5. Hydrogen

- 4.2.6. Dimethyl Ether

- 4.3. Liquid Fuels

- 4.4. Gaseous Fuels

-

5. Geography

- 5.1. United States

- 5.2. Canada

- 5.3. Mexico

- 5.4. Rest of North America

North America Syngas Market Segmentation By Geography

- 1. United States

- 2. Canada

- 3. Mexico

- 4. Rest of North America

North America Syngas Market Regional Market Share

Geographic Coverage of North America Syngas Market

North America Syngas Market REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of > 8.00% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1. ; Feedstock Flexibility for Syngas Production; Growing Demand for Electricity; Growing Chemical Industry

- 3.3. Market Restrains

- 3.3.1. ; High Capital Investment and Funding

- 3.4. Market Trends

- 3.4.1. Increasing Usage in Power Generation Industry

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. North America Syngas Market Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Feedstock

- 5.1.1. Coal

- 5.1.2. Natural Gas

- 5.1.3. Petroleum

- 5.1.4. Pet-coke

- 5.1.5. Biomass

- 5.2. Market Analysis, Insights and Forecast - by Technology

- 5.2.1. Steam Reforming

- 5.2.2. Partial Oxidation

- 5.2.3. Auto-thermal Reforming

- 5.2.4. Combined or Two-step Reforming

- 5.2.5. Biomass Gasification

- 5.3. Market Analysis, Insights and Forecast - by Gasifier Type

- 5.3.1. Fixed Bed

- 5.3.2. Entrained Flow

- 5.3.3. Fluidized Bed

- 5.4. Market Analysis, Insights and Forecast - by Application

- 5.4.1. Power Generation

- 5.4.2. Chemicals

- 5.4.2.1. Methanol

- 5.4.2.2. Ammonia

- 5.4.2.3. Oxo Chemicals

- 5.4.2.4. n-Butanol

- 5.4.2.5. Hydrogen

- 5.4.2.6. Dimethyl Ether

- 5.4.3. Liquid Fuels

- 5.4.4. Gaseous Fuels

- 5.5. Market Analysis, Insights and Forecast - by Geography

- 5.5.1. United States

- 5.5.2. Canada

- 5.5.3. Mexico

- 5.5.4. Rest of North America

- 5.6. Market Analysis, Insights and Forecast - by Region

- 5.6.1. United States

- 5.6.2. Canada

- 5.6.3. Mexico

- 5.6.4. Rest of North America

- 5.1. Market Analysis, Insights and Forecast - by Feedstock

- 6. United States North America Syngas Market Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Feedstock

- 6.1.1. Coal

- 6.1.2. Natural Gas

- 6.1.3. Petroleum

- 6.1.4. Pet-coke

- 6.1.5. Biomass

- 6.2. Market Analysis, Insights and Forecast - by Technology

- 6.2.1. Steam Reforming

- 6.2.2. Partial Oxidation

- 6.2.3. Auto-thermal Reforming

- 6.2.4. Combined or Two-step Reforming

- 6.2.5. Biomass Gasification

- 6.3. Market Analysis, Insights and Forecast - by Gasifier Type

- 6.3.1. Fixed Bed

- 6.3.2. Entrained Flow

- 6.3.3. Fluidized Bed

- 6.4. Market Analysis, Insights and Forecast - by Application

- 6.4.1. Power Generation

- 6.4.2. Chemicals

- 6.4.2.1. Methanol

- 6.4.2.2. Ammonia

- 6.4.2.3. Oxo Chemicals

- 6.4.2.4. n-Butanol

- 6.4.2.5. Hydrogen

- 6.4.2.6. Dimethyl Ether

- 6.4.3. Liquid Fuels

- 6.4.4. Gaseous Fuels

- 6.5. Market Analysis, Insights and Forecast - by Geography

- 6.5.1. United States

- 6.5.2. Canada

- 6.5.3. Mexico

- 6.5.4. Rest of North America

- 6.1. Market Analysis, Insights and Forecast - by Feedstock

- 7. Canada North America Syngas Market Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Feedstock

- 7.1.1. Coal

- 7.1.2. Natural Gas

- 7.1.3. Petroleum

- 7.1.4. Pet-coke

- 7.1.5. Biomass

- 7.2. Market Analysis, Insights and Forecast - by Technology

- 7.2.1. Steam Reforming

- 7.2.2. Partial Oxidation

- 7.2.3. Auto-thermal Reforming

- 7.2.4. Combined or Two-step Reforming

- 7.2.5. Biomass Gasification

- 7.3. Market Analysis, Insights and Forecast - by Gasifier Type

- 7.3.1. Fixed Bed

- 7.3.2. Entrained Flow

- 7.3.3. Fluidized Bed

- 7.4. Market Analysis, Insights and Forecast - by Application

- 7.4.1. Power Generation

- 7.4.2. Chemicals

- 7.4.2.1. Methanol

- 7.4.2.2. Ammonia

- 7.4.2.3. Oxo Chemicals

- 7.4.2.4. n-Butanol

- 7.4.2.5. Hydrogen

- 7.4.2.6. Dimethyl Ether

- 7.4.3. Liquid Fuels

- 7.4.4. Gaseous Fuels

- 7.5. Market Analysis, Insights and Forecast - by Geography

- 7.5.1. United States

- 7.5.2. Canada

- 7.5.3. Mexico

- 7.5.4. Rest of North America

- 7.1. Market Analysis, Insights and Forecast - by Feedstock

- 8. Mexico North America Syngas Market Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Feedstock

- 8.1.1. Coal

- 8.1.2. Natural Gas

- 8.1.3. Petroleum

- 8.1.4. Pet-coke

- 8.1.5. Biomass

- 8.2. Market Analysis, Insights and Forecast - by Technology

- 8.2.1. Steam Reforming

- 8.2.2. Partial Oxidation

- 8.2.3. Auto-thermal Reforming

- 8.2.4. Combined or Two-step Reforming

- 8.2.5. Biomass Gasification

- 8.3. Market Analysis, Insights and Forecast - by Gasifier Type

- 8.3.1. Fixed Bed

- 8.3.2. Entrained Flow

- 8.3.3. Fluidized Bed

- 8.4. Market Analysis, Insights and Forecast - by Application

- 8.4.1. Power Generation

- 8.4.2. Chemicals

- 8.4.2.1. Methanol

- 8.4.2.2. Ammonia

- 8.4.2.3. Oxo Chemicals

- 8.4.2.4. n-Butanol

- 8.4.2.5. Hydrogen

- 8.4.2.6. Dimethyl Ether

- 8.4.3. Liquid Fuels

- 8.4.4. Gaseous Fuels

- 8.5. Market Analysis, Insights and Forecast - by Geography

- 8.5.1. United States

- 8.5.2. Canada

- 8.5.3. Mexico

- 8.5.4. Rest of North America

- 8.1. Market Analysis, Insights and Forecast - by Feedstock

- 9. Rest of North America North America Syngas Market Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Feedstock

- 9.1.1. Coal

- 9.1.2. Natural Gas

- 9.1.3. Petroleum

- 9.1.4. Pet-coke

- 9.1.5. Biomass

- 9.2. Market Analysis, Insights and Forecast - by Technology

- 9.2.1. Steam Reforming

- 9.2.2. Partial Oxidation

- 9.2.3. Auto-thermal Reforming

- 9.2.4. Combined or Two-step Reforming

- 9.2.5. Biomass Gasification

- 9.3. Market Analysis, Insights and Forecast - by Gasifier Type

- 9.3.1. Fixed Bed

- 9.3.2. Entrained Flow

- 9.3.3. Fluidized Bed

- 9.4. Market Analysis, Insights and Forecast - by Application

- 9.4.1. Power Generation

- 9.4.2. Chemicals

- 9.4.2.1. Methanol

- 9.4.2.2. Ammonia

- 9.4.2.3. Oxo Chemicals

- 9.4.2.4. n-Butanol

- 9.4.2.5. Hydrogen

- 9.4.2.6. Dimethyl Ether

- 9.4.3. Liquid Fuels

- 9.4.4. Gaseous Fuels

- 9.5. Market Analysis, Insights and Forecast - by Geography

- 9.5.1. United States

- 9.5.2. Canada

- 9.5.3. Mexico

- 9.5.4. Rest of North America

- 9.1. Market Analysis, Insights and Forecast - by Feedstock

- 10. Competitive Analysis

- 10.1. Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 Haldor Topsoe A/S

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 TechnipFMC PLC*List Not Exhaustive

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 General Electric

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 Air Products and Chemicals Inc

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 Royal Dutch Shell plc

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Siemens

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 KBR Inc

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 BASF SE

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 Sasol

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Linde plc

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.11 SynGas Technology LLC

- 10.2.11.1. Overview

- 10.2.11.2. Products

- 10.2.11.3. SWOT Analysis

- 10.2.11.4. Recent Developments

- 10.2.11.5. Financials (Based on Availability)

- 10.2.12 Air Liquide

- 10.2.12.1. Overview

- 10.2.12.2. Products

- 10.2.12.3. SWOT Analysis

- 10.2.12.4. Recent Developments

- 10.2.12.5. Financials (Based on Availability)

- 10.2.13 BP p l c

- 10.2.13.1. Overview

- 10.2.13.2. Products

- 10.2.13.3. SWOT Analysis

- 10.2.13.4. Recent Developments

- 10.2.13.5. Financials (Based on Availability)

- 10.2.14 Dakota Gasification Company Inc

- 10.2.14.1. Overview

- 10.2.14.2. Products

- 10.2.14.3. SWOT Analysis

- 10.2.14.4. Recent Developments

- 10.2.14.5. Financials (Based on Availability)

- 10.2.1 Haldor Topsoe A/S

List of Figures

- Figure 1: North America Syngas Market Revenue Breakdown (Million, %) by Product 2025 & 2033

- Figure 2: North America Syngas Market Share (%) by Company 2025

List of Tables

- Table 1: North America Syngas Market Revenue Million Forecast, by Feedstock 2020 & 2033

- Table 2: North America Syngas Market Volume K Tons Forecast, by Feedstock 2020 & 2033

- Table 3: North America Syngas Market Revenue Million Forecast, by Technology 2020 & 2033

- Table 4: North America Syngas Market Volume K Tons Forecast, by Technology 2020 & 2033

- Table 5: North America Syngas Market Revenue Million Forecast, by Gasifier Type 2020 & 2033

- Table 6: North America Syngas Market Volume K Tons Forecast, by Gasifier Type 2020 & 2033

- Table 7: North America Syngas Market Revenue Million Forecast, by Application 2020 & 2033

- Table 8: North America Syngas Market Volume K Tons Forecast, by Application 2020 & 2033

- Table 9: North America Syngas Market Revenue Million Forecast, by Geography 2020 & 2033

- Table 10: North America Syngas Market Volume K Tons Forecast, by Geography 2020 & 2033

- Table 11: North America Syngas Market Revenue Million Forecast, by Region 2020 & 2033

- Table 12: North America Syngas Market Volume K Tons Forecast, by Region 2020 & 2033

- Table 13: North America Syngas Market Revenue Million Forecast, by Feedstock 2020 & 2033

- Table 14: North America Syngas Market Volume K Tons Forecast, by Feedstock 2020 & 2033

- Table 15: North America Syngas Market Revenue Million Forecast, by Technology 2020 & 2033

- Table 16: North America Syngas Market Volume K Tons Forecast, by Technology 2020 & 2033

- Table 17: North America Syngas Market Revenue Million Forecast, by Gasifier Type 2020 & 2033

- Table 18: North America Syngas Market Volume K Tons Forecast, by Gasifier Type 2020 & 2033

- Table 19: North America Syngas Market Revenue Million Forecast, by Application 2020 & 2033

- Table 20: North America Syngas Market Volume K Tons Forecast, by Application 2020 & 2033

- Table 21: North America Syngas Market Revenue Million Forecast, by Geography 2020 & 2033

- Table 22: North America Syngas Market Volume K Tons Forecast, by Geography 2020 & 2033

- Table 23: North America Syngas Market Revenue Million Forecast, by Country 2020 & 2033

- Table 24: North America Syngas Market Volume K Tons Forecast, by Country 2020 & 2033

- Table 25: North America Syngas Market Revenue Million Forecast, by Feedstock 2020 & 2033

- Table 26: North America Syngas Market Volume K Tons Forecast, by Feedstock 2020 & 2033

- Table 27: North America Syngas Market Revenue Million Forecast, by Technology 2020 & 2033

- Table 28: North America Syngas Market Volume K Tons Forecast, by Technology 2020 & 2033

- Table 29: North America Syngas Market Revenue Million Forecast, by Gasifier Type 2020 & 2033

- Table 30: North America Syngas Market Volume K Tons Forecast, by Gasifier Type 2020 & 2033

- Table 31: North America Syngas Market Revenue Million Forecast, by Application 2020 & 2033

- Table 32: North America Syngas Market Volume K Tons Forecast, by Application 2020 & 2033

- Table 33: North America Syngas Market Revenue Million Forecast, by Geography 2020 & 2033

- Table 34: North America Syngas Market Volume K Tons Forecast, by Geography 2020 & 2033

- Table 35: North America Syngas Market Revenue Million Forecast, by Country 2020 & 2033

- Table 36: North America Syngas Market Volume K Tons Forecast, by Country 2020 & 2033

- Table 37: North America Syngas Market Revenue Million Forecast, by Feedstock 2020 & 2033

- Table 38: North America Syngas Market Volume K Tons Forecast, by Feedstock 2020 & 2033

- Table 39: North America Syngas Market Revenue Million Forecast, by Technology 2020 & 2033

- Table 40: North America Syngas Market Volume K Tons Forecast, by Technology 2020 & 2033

- Table 41: North America Syngas Market Revenue Million Forecast, by Gasifier Type 2020 & 2033

- Table 42: North America Syngas Market Volume K Tons Forecast, by Gasifier Type 2020 & 2033

- Table 43: North America Syngas Market Revenue Million Forecast, by Application 2020 & 2033

- Table 44: North America Syngas Market Volume K Tons Forecast, by Application 2020 & 2033

- Table 45: North America Syngas Market Revenue Million Forecast, by Geography 2020 & 2033

- Table 46: North America Syngas Market Volume K Tons Forecast, by Geography 2020 & 2033

- Table 47: North America Syngas Market Revenue Million Forecast, by Country 2020 & 2033

- Table 48: North America Syngas Market Volume K Tons Forecast, by Country 2020 & 2033

- Table 49: North America Syngas Market Revenue Million Forecast, by Feedstock 2020 & 2033

- Table 50: North America Syngas Market Volume K Tons Forecast, by Feedstock 2020 & 2033

- Table 51: North America Syngas Market Revenue Million Forecast, by Technology 2020 & 2033

- Table 52: North America Syngas Market Volume K Tons Forecast, by Technology 2020 & 2033

- Table 53: North America Syngas Market Revenue Million Forecast, by Gasifier Type 2020 & 2033

- Table 54: North America Syngas Market Volume K Tons Forecast, by Gasifier Type 2020 & 2033

- Table 55: North America Syngas Market Revenue Million Forecast, by Application 2020 & 2033

- Table 56: North America Syngas Market Volume K Tons Forecast, by Application 2020 & 2033

- Table 57: North America Syngas Market Revenue Million Forecast, by Geography 2020 & 2033

- Table 58: North America Syngas Market Volume K Tons Forecast, by Geography 2020 & 2033

- Table 59: North America Syngas Market Revenue Million Forecast, by Country 2020 & 2033

- Table 60: North America Syngas Market Volume K Tons Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the North America Syngas Market?

The projected CAGR is approximately > 8.00%.

2. Which companies are prominent players in the North America Syngas Market?

Key companies in the market include Haldor Topsoe A/S, TechnipFMC PLC*List Not Exhaustive, General Electric, Air Products and Chemicals Inc, Royal Dutch Shell plc, Siemens, KBR Inc, BASF SE, Sasol, Linde plc, SynGas Technology LLC, Air Liquide, BP p l c, Dakota Gasification Company Inc.

3. What are the main segments of the North America Syngas Market?

The market segments include Feedstock, Technology, Gasifier Type, Application, Geography.

4. Can you provide details about the market size?

The market size is estimated to be USD 230.05 Million as of 2022.

5. What are some drivers contributing to market growth?

; Feedstock Flexibility for Syngas Production; Growing Demand for Electricity; Growing Chemical Industry.

6. What are the notable trends driving market growth?

Increasing Usage in Power Generation Industry.

7. Are there any restraints impacting market growth?

; High Capital Investment and Funding.

8. Can you provide examples of recent developments in the market?

Investments in carbon capture and storage technologies

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in Million and volume, measured in K Tons.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "North America Syngas Market," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the North America Syngas Market report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the North America Syngas Market?

To stay informed about further developments, trends, and reports in the North America Syngas Market, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence