Key Insights

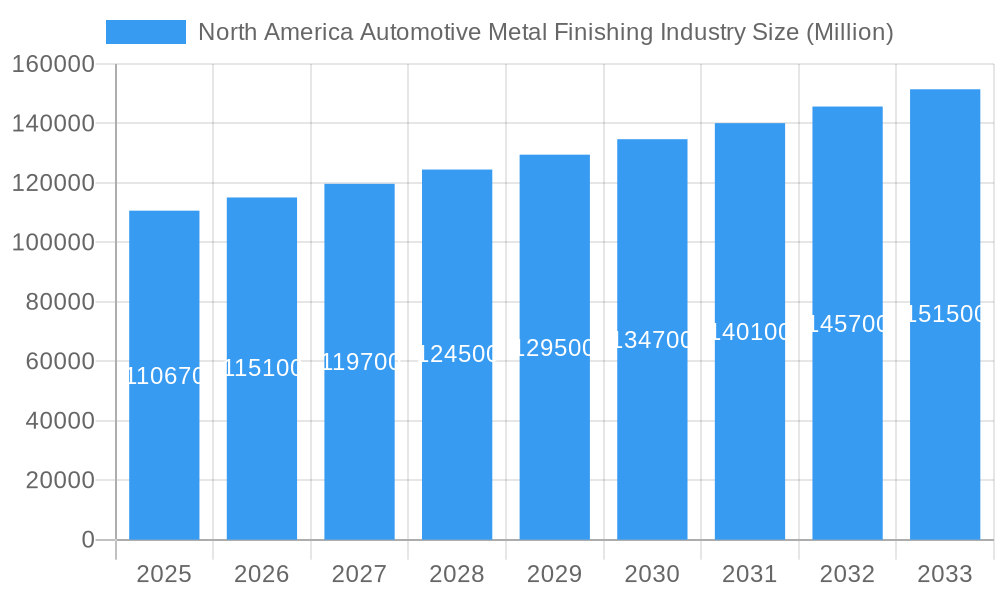

The North American automotive metal finishing industry is poised for steady growth, projected to reach a market size of $110.67 billion in 2025, expanding at a Compound Annual Growth Rate (CAGR) of 4% through 2033. This robust expansion is primarily driven by the increasing demand for lightweight and durable automotive components, advancements in electric vehicle (EV) technology requiring specialized surface treatments for battery components and powertrain parts, and stringent regulatory requirements for corrosion resistance and environmental compliance. The automotive sector, a cornerstone of the North American economy, relies heavily on metal finishing for aesthetic appeal, functional performance, and extended product lifespan of critical parts like engine components, chassis elements, and interior/exterior trim. The ongoing innovation in material science and the adoption of advanced manufacturing techniques further fuel the need for sophisticated metal finishing processes.

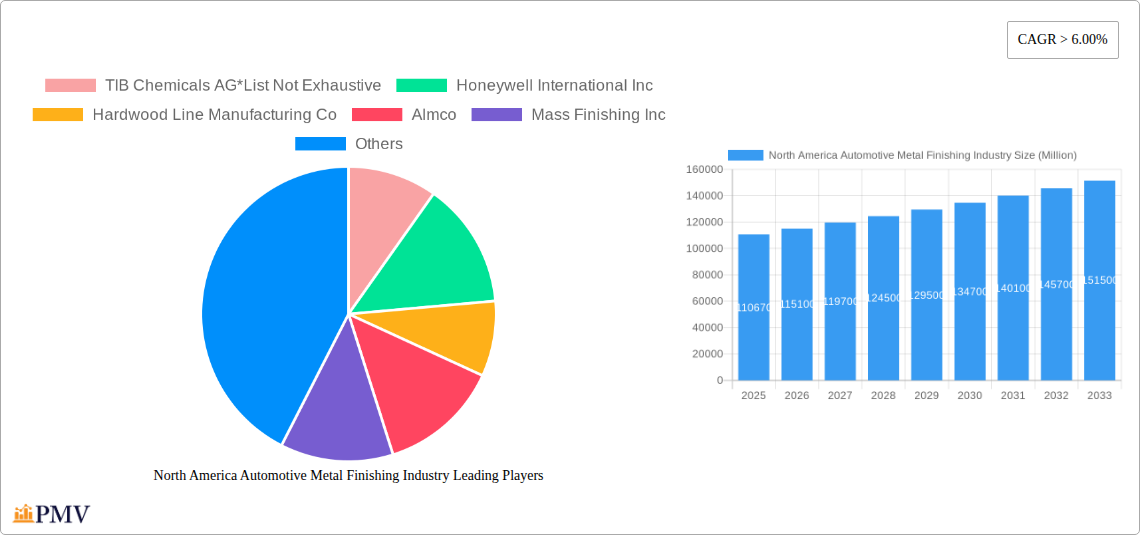

North America Automotive Metal Finishing Industry Market Size (In Billion)

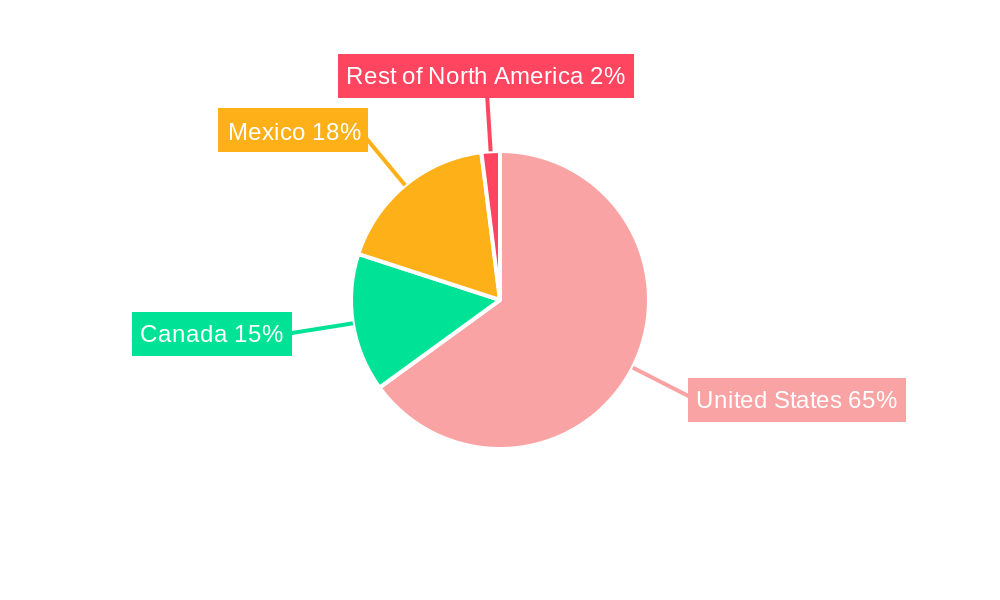

The market is segmented across various finishing types, with Inorganic Metal Finishing, encompassing crucial processes like electroplating, galvanization, and conversion coatings, holding a dominant share. Application-wise, the automotive sector continues to be the largest consumer, followed by appliances, hardware, and electronics. Geographically, the United States leads the market, propelled by its extensive automotive manufacturing base and technological advancements, with Canada and Mexico also contributing significantly to regional growth. Key trends include a growing emphasis on sustainable and eco-friendly finishing solutions, the adoption of automated and robotic finishing systems for improved efficiency and precision, and the development of multi-functional coatings that offer enhanced properties such as wear resistance, thermal conductivity, and electromagnetic shielding. While the market demonstrates strong growth potential, rising raw material costs for plating chemicals and the initial investment required for adopting advanced finishing technologies present potential restraints.

North America Automotive Metal Finishing Industry Company Market Share

This in-depth report provides a comprehensive analysis of the North America Automotive Metal Finishing Industry market, covering the historical period from 2019 to 2024, the base year of 2025, and a detailed forecast from 2025 to 2033. With an estimated market size projected to reach XX billion USD in 2025 and a Compound Annual Growth Rate (CAGR) of XX% during the forecast period, this study delves into critical market dynamics, competitive landscapes, technological advancements, and regional segmentation. We explore key growth drivers, emerging challenges, and strategic opportunities within this vital sector, offering actionable insights for stakeholders seeking to navigate and capitalize on the evolving automotive metal finishing market. This report leverages high-ranking keywords such as "automotive metal finishing," "North America metal coating," "electroplating automotive," "galvanization trends," "surface preparation solutions," "metal finishing technologies," and "automotive coatings market" to ensure maximum search visibility and engagement with industry professionals.

North America Automotive Metal Finishing Industry Market Structure & Competitive Dynamics

The North America Automotive Metal Finishing Industry is characterized by a moderately concentrated market structure, with a blend of large multinational corporations and specialized regional players. Innovation ecosystems are driven by the automotive sector's constant demand for enhanced performance, durability, and aesthetic appeal. Regulatory frameworks, particularly concerning environmental compliance and material safety, significantly influence operational strategies and product development. The industry faces constant pressure from product substitutes, including advanced polymer coatings and novel material composites, necessitating continuous innovation in metal finishing techniques. End-user trends are dominated by the push for lightweighting, improved fuel efficiency, and advanced driver-assistance systems (ADAS), all of which rely on specialized metal finishing for component integrity and functionality. Merger and acquisition (M&A) activities are strategic, focusing on consolidating market share, acquiring new technologies, and expanding geographical reach. For instance, acquisitions in the past few years have focused on expanding capabilities in advanced pretreatment and eco-friendly plating solutions. Key players are actively investing in research and development, aiming to introduce cost-effective and sustainable finishing processes. The total M&A deal value in the past five years is estimated to be in the range of XX billion USD. Market share is distributed with leading players holding significant portions, while smaller, agile companies carve out niches in specialized applications.

North America Automotive Metal Finishing Industry Industry Trends & Insights

The North America Automotive Metal Finishing Industry is experiencing robust growth, fueled by an escalating demand for aesthetically pleasing, corrosion-resistant, and functional automotive components. The market is projected to reach XX billion USD by 2033, exhibiting a CAGR of XX% from the base year of 2025. Key growth drivers include the increasing production of electric vehicles (EVs), which require specialized corrosion protection for battery components and lightweight chassis structures, and the continuous advancements in automotive design, demanding superior finishes for both interior and exterior parts. Technological disruptions, such as the growing adoption of advanced plating technologies like electroless nickel plating for enhanced wear resistance and the integration of nanotechnology for superior surface properties, are reshaping the competitive landscape. Consumer preferences are increasingly leaning towards sustainable and environmentally friendly finishing processes, prompting manufacturers to invest in low-VOC (Volatile Organic Compound) coatings and efficient wastewater treatment systems. The competitive dynamics are intensifying, with a focus on offering integrated solutions encompassing pretreatment, finishing, and post-treatment processes. Market penetration for advanced metal finishing solutions is steadily increasing, driven by the automotive industry's commitment to product quality and longevity. The shift towards smart manufacturing and Industry 4.0 principles is also influencing operational efficiency, with automation and real-time monitoring becoming integral to metal finishing plants. Furthermore, the stringent safety and performance regulations imposed by automotive manufacturers are pushing for higher quality standards and more sophisticated testing protocols within the finishing sector.

Dominant Markets & Segments in North America Automotive Metal Finishing Industry

The United States stands as the dominant market within the North America Automotive Metal Finishing Industry, driven by its large automotive manufacturing base, significant R&D investments, and strong consumer demand for advanced vehicle features. Within the Type segmentation, Inorganic Metal Finishing holds the largest market share, with Electroplating and Pretreatment/Surface Preparation being the most significant sub-segments. Electroplating is crucial for providing corrosion resistance, wear durability, and decorative finishes to a wide array of automotive parts, from engine components to trim elements. Pretreatment and Surface Preparation are foundational, ensuring optimal adhesion and performance of subsequent finishing layers, crucial for long-term component integrity. Galvanization also plays a vital role, particularly in protecting structural steel components from corrosion.

In terms of Application, the Automotive segment itself is the primary driver, encompassing a vast range of components. Other significant applications contributing to the overall market include Appliances and Electronics, which often utilize similar metal finishing techniques for durability and aesthetics. The Aerospace sector, though smaller than automotive, contributes significantly due to its high-value, stringent quality requirements.

Geographically, the United States leads, followed by Canada and Mexico, each with distinct contributions. Canada benefits from its established automotive manufacturing presence, while Mexico's role as a major automotive production hub for North America drives substantial demand for metal finishing services, particularly for export-oriented manufacturing. The Rest of North America is a smaller but growing segment, influenced by specific industrial needs and emerging manufacturing capabilities.

Key drivers for the dominance of the United States include:

- Robust Automotive Production: A substantial number of automotive assembly plants and component suppliers operate within the US.

- Technological Innovation: Leading research institutions and private companies continuously develop advanced metal finishing solutions.

- Stringent Quality Standards: The high expectations of US automotive manufacturers translate into demand for premium finishing services.

- Economic Policies: Favorable trade policies and government incentives for manufacturing contribute to market growth.

Within the Type segmentation, Electroplating is projected to continue its dominance, with its versatility in applying various metals like chrome, nickel, and zinc to enhance aesthetics and protective properties. The increasing demand for lightweighting and corrosion resistance in EVs further bolsters the need for advanced electroplating techniques.

North America Automotive Metal Finishing Industry Product Innovations

Product innovations in the North America Automotive Metal Finishing Industry are largely driven by the pursuit of enhanced performance, environmental sustainability, and cost-effectiveness. Recent developments include advanced pretreatment solutions that reduce water consumption and eliminate hazardous chemicals, and novel electroplating formulations offering superior corrosion resistance and reduced environmental impact. Nanotechnology integration is yielding finishes with exceptional hardness, scratch resistance, and self-healing properties, ideal for demanding automotive applications. For instance, the development of thinner yet more durable conversion coatings and specialized anodizing processes for aluminum alloys are gaining traction. These innovations provide competitive advantages by enabling manufacturers to meet increasingly stringent OEM specifications and evolving consumer expectations for vehicle longevity and aesthetic appeal.

Report Segmentation & Scope

This report meticulously segments the North America Automotive Metal Finishing Industry by Type, Application, and Geography. The Type segmentation encompasses: Inorganic Metal Finishing (including Cladding, Pretreatment/Surface Preparation, Consumables and Spares, Electroplating, Galvanization, Electro Less Plating, Conversion Coatings, Anodizing, Electro Polishing), Organic Metal Finishing, and Hybrid Metal Finishing. The Application segmentation covers: Automotive, Appliances, Hardware, Jewelry, Aerospace, Heavy Equipment, Medical Devices, Electronics, Construction, and Other Applications. Geographically, the market is divided into the United States, Canada, Mexico, and the Rest of North America. Growth projections indicate a strong upward trajectory for the Automotive application segment, driven by increasing vehicle production and the demand for advanced finishes. Inorganic Metal Finishing, particularly Electroplating and Pretreatment/Surface Preparation, will continue to dominate the Type segment, with emerging opportunities in Hybrid Metal Finishing for specialized applications. The United States is expected to maintain its leading position in terms of market size and growth.

Key Drivers of North America Automotive Metal Finishing Industry Growth

Several key factors are driving the growth of the North America Automotive Metal Finishing Industry. The relentless pursuit of enhanced vehicle performance, durability, and aesthetics by automotive manufacturers is a primary catalyst. The increasing adoption of electric vehicles (EVs) necessitates specialized, high-performance metal finishing for components like battery casings and lightweight chassis, further boosting demand. Technological advancements in plating and surface treatment technologies are enabling more efficient, environmentally friendly, and cost-effective solutions. Growing regulatory pressures promoting sustainable practices are also pushing innovation towards eco-friendly finishing processes. Furthermore, the robust aftermarket demand for vehicle maintenance and repair, which often involves refinishing and component replacement, contributes significantly to market expansion.

Challenges in the North America Automotive Metal Finishing Industry Sector

Despite the positive growth trajectory, the North America Automotive Metal Finishing Industry faces several challenges. Stringent environmental regulations, particularly concerning waste disposal and the use of hazardous chemicals, necessitate significant investment in compliance and advanced treatment technologies, thereby increasing operational costs. Fluctuations in raw material prices, such as nickel, zinc, and chromium, can impact profitability and pricing strategies. The skilled labor shortage within the manufacturing sector, including specialized roles in metal finishing, poses a significant operational hurdle. Furthermore, intense competition from both domestic and international players, as well as the increasing adoption of alternative materials and coating technologies, put pressure on market share and profit margins. Supply chain disruptions, as experienced in recent years, can also impact the availability of essential chemicals and equipment.

Leading Players in the North America Automotive Metal Finishing Industry Market

- TIB Chemicals AG

- Honeywell International Inc

- Hardwood Line Manufacturing Co

- Almco

- Mass Finishing Inc

- Guyson Corporation

- OC Oerlikon Management AG

- C Uyemura & Co Ltd

- POSCO

- Sequa (The Carlyle Group)

- OTEC Precision Finish Inc

- Linde plc

- Luster-on Products Inc

- A E Aubin Company

- Giant Finishing Inc

Key Developments in North America Automotive Metal Finishing Industry Sector

- May 2019: Guyson Corporation announced the availability of its new metal finishing technology, Multiblast 3D, a blasting chamber specifically designed for the post-processing of 3D printed parts for HP Jet Fusion 500/300 Series 3D printers.

- May 2019: OTEC Precision Finish Inc. developed a new surface finishing process for aero engine turbine and compressor blades, known as the stream-finishing process, where the blades are clamped and lowered.

Strategic North America Automotive Metal Finishing Industry Market Outlook

The strategic outlook for the North America Automotive Metal Finishing Industry is highly promising, driven by sustained demand from the burgeoning automotive sector and its increasing integration with advanced technologies. The ongoing transition towards electric vehicles presents a significant growth accelerator, creating a demand for specialized finishes that enhance battery performance and structural integrity. Furthermore, the industry's commitment to sustainability and eco-friendly processes will continue to drive innovation in the development of green finishing solutions, opening new market avenues. Strategic opportunities lie in offering integrated, end-to-end finishing solutions that encompass pretreatment, plating, and post-treatment, catering to the evolving needs of OEMs. Investments in advanced automation and digital technologies will be crucial for enhancing operational efficiency and competitiveness. Collaborations between metal finishing providers and automotive manufacturers to co-develop next-generation surface treatments will also be a key growth enabler, ensuring that the industry remains at the forefront of automotive innovation and meets future mobility demands.

North America Automotive Metal Finishing Industry Segmentation

-

1. Type

-

1.1. Inorganic Metal Finishing

- 1.1.1. Cladding

- 1.1.2. Pretreatment/Surface Preparation

- 1.1.3. Consumables and Spares

- 1.1.4. Electroplating

- 1.1.5. Galvanization

- 1.1.6. Electro Less Plating

- 1.1.7. Conversion Coatings

- 1.1.8. Anodizing

- 1.1.9. Electro Polishing

- 1.2. Organic Metal Finishing

- 1.3. Hybrid Metal Finishing

-

1.1. Inorganic Metal Finishing

-

2. Application

- 2.1. Automotive

- 2.2. Appliances

- 2.3. Hardware

- 2.4. Jewelry

- 2.5. Aerospace

- 2.6. Heavy Equipment

- 2.7. Medical Devices

- 2.8. Electronics

- 2.9. Construction

- 2.10. Other Applications

-

3. Geography

- 3.1. United States

- 3.2. Canada

- 3.3. Mexico

- 3.4. Rest of North America

North America Automotive Metal Finishing Industry Segmentation By Geography

- 1. United States

- 2. Canada

- 3. Mexico

- 4. Rest of North America

North America Automotive Metal Finishing Industry Regional Market Share

Geographic Coverage of North America Automotive Metal Finishing Industry

North America Automotive Metal Finishing Industry REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2020-2034 |

| Base Year | 2025 |

| Estimated Year | 2026 |

| Forecast Period | 2026-2034 |

| Historical Period | 2020-2025 |

| Growth Rate | CAGR of 4% from 2020-2034 |

| Segmentation |

|

Table of Contents

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.2.1 Increasing Requirement for Durable

- 3.2.2 Wear-resistant

- 3.2.3 and Long-lasting Metal Products; Other Drivers

- 3.3. Market Restrains

- 3.3.1. Environmental Restrictions on Some Chemicals; Increasing Replacement of Metal by Plastics; Impact of COVID-19 Pandemic

- 3.4. Market Trends

- 3.4.1. Automotive Segment to Dominate the Market

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. North America Automotive Metal Finishing Industry Analysis, Insights and Forecast, 2020-2032

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Inorganic Metal Finishing

- 5.1.1.1. Cladding

- 5.1.1.2. Pretreatment/Surface Preparation

- 5.1.1.3. Consumables and Spares

- 5.1.1.4. Electroplating

- 5.1.1.5. Galvanization

- 5.1.1.6. Electro Less Plating

- 5.1.1.7. Conversion Coatings

- 5.1.1.8. Anodizing

- 5.1.1.9. Electro Polishing

- 5.1.2. Organic Metal Finishing

- 5.1.3. Hybrid Metal Finishing

- 5.1.1. Inorganic Metal Finishing

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Automotive

- 5.2.2. Appliances

- 5.2.3. Hardware

- 5.2.4. Jewelry

- 5.2.5. Aerospace

- 5.2.6. Heavy Equipment

- 5.2.7. Medical Devices

- 5.2.8. Electronics

- 5.2.9. Construction

- 5.2.10. Other Applications

- 5.3. Market Analysis, Insights and Forecast - by Geography

- 5.3.1. United States

- 5.3.2. Canada

- 5.3.3. Mexico

- 5.3.4. Rest of North America

- 5.4. Market Analysis, Insights and Forecast - by Region

- 5.4.1. United States

- 5.4.2. Canada

- 5.4.3. Mexico

- 5.4.4. Rest of North America

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. United States North America Automotive Metal Finishing Industry Analysis, Insights and Forecast, 2020-2032

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Inorganic Metal Finishing

- 6.1.1.1. Cladding

- 6.1.1.2. Pretreatment/Surface Preparation

- 6.1.1.3. Consumables and Spares

- 6.1.1.4. Electroplating

- 6.1.1.5. Galvanization

- 6.1.1.6. Electro Less Plating

- 6.1.1.7. Conversion Coatings

- 6.1.1.8. Anodizing

- 6.1.1.9. Electro Polishing

- 6.1.2. Organic Metal Finishing

- 6.1.3. Hybrid Metal Finishing

- 6.1.1. Inorganic Metal Finishing

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Automotive

- 6.2.2. Appliances

- 6.2.3. Hardware

- 6.2.4. Jewelry

- 6.2.5. Aerospace

- 6.2.6. Heavy Equipment

- 6.2.7. Medical Devices

- 6.2.8. Electronics

- 6.2.9. Construction

- 6.2.10. Other Applications

- 6.3. Market Analysis, Insights and Forecast - by Geography

- 6.3.1. United States

- 6.3.2. Canada

- 6.3.3. Mexico

- 6.3.4. Rest of North America

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. Canada North America Automotive Metal Finishing Industry Analysis, Insights and Forecast, 2020-2032

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Inorganic Metal Finishing

- 7.1.1.1. Cladding

- 7.1.1.2. Pretreatment/Surface Preparation

- 7.1.1.3. Consumables and Spares

- 7.1.1.4. Electroplating

- 7.1.1.5. Galvanization

- 7.1.1.6. Electro Less Plating

- 7.1.1.7. Conversion Coatings

- 7.1.1.8. Anodizing

- 7.1.1.9. Electro Polishing

- 7.1.2. Organic Metal Finishing

- 7.1.3. Hybrid Metal Finishing

- 7.1.1. Inorganic Metal Finishing

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Automotive

- 7.2.2. Appliances

- 7.2.3. Hardware

- 7.2.4. Jewelry

- 7.2.5. Aerospace

- 7.2.6. Heavy Equipment

- 7.2.7. Medical Devices

- 7.2.8. Electronics

- 7.2.9. Construction

- 7.2.10. Other Applications

- 7.3. Market Analysis, Insights and Forecast - by Geography

- 7.3.1. United States

- 7.3.2. Canada

- 7.3.3. Mexico

- 7.3.4. Rest of North America

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Mexico North America Automotive Metal Finishing Industry Analysis, Insights and Forecast, 2020-2032

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Inorganic Metal Finishing

- 8.1.1.1. Cladding

- 8.1.1.2. Pretreatment/Surface Preparation

- 8.1.1.3. Consumables and Spares

- 8.1.1.4. Electroplating

- 8.1.1.5. Galvanization

- 8.1.1.6. Electro Less Plating

- 8.1.1.7. Conversion Coatings

- 8.1.1.8. Anodizing

- 8.1.1.9. Electro Polishing

- 8.1.2. Organic Metal Finishing

- 8.1.3. Hybrid Metal Finishing

- 8.1.1. Inorganic Metal Finishing

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Automotive

- 8.2.2. Appliances

- 8.2.3. Hardware

- 8.2.4. Jewelry

- 8.2.5. Aerospace

- 8.2.6. Heavy Equipment

- 8.2.7. Medical Devices

- 8.2.8. Electronics

- 8.2.9. Construction

- 8.2.10. Other Applications

- 8.3. Market Analysis, Insights and Forecast - by Geography

- 8.3.1. United States

- 8.3.2. Canada

- 8.3.3. Mexico

- 8.3.4. Rest of North America

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Rest of North America North America Automotive Metal Finishing Industry Analysis, Insights and Forecast, 2020-2032

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Inorganic Metal Finishing

- 9.1.1.1. Cladding

- 9.1.1.2. Pretreatment/Surface Preparation

- 9.1.1.3. Consumables and Spares

- 9.1.1.4. Electroplating

- 9.1.1.5. Galvanization

- 9.1.1.6. Electro Less Plating

- 9.1.1.7. Conversion Coatings

- 9.1.1.8. Anodizing

- 9.1.1.9. Electro Polishing

- 9.1.2. Organic Metal Finishing

- 9.1.3. Hybrid Metal Finishing

- 9.1.1. Inorganic Metal Finishing

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Automotive

- 9.2.2. Appliances

- 9.2.3. Hardware

- 9.2.4. Jewelry

- 9.2.5. Aerospace

- 9.2.6. Heavy Equipment

- 9.2.7. Medical Devices

- 9.2.8. Electronics

- 9.2.9. Construction

- 9.2.10. Other Applications

- 9.3. Market Analysis, Insights and Forecast - by Geography

- 9.3.1. United States

- 9.3.2. Canada

- 9.3.3. Mexico

- 9.3.4. Rest of North America

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Competitive Analysis

- 10.1. Market Share Analysis 2025

- 10.2. Company Profiles

- 10.2.1 TIB Chemicals AG*List Not Exhaustive

- 10.2.1.1. Overview

- 10.2.1.2. Products

- 10.2.1.3. SWOT Analysis

- 10.2.1.4. Recent Developments

- 10.2.1.5. Financials (Based on Availability)

- 10.2.2 Honeywell International Inc

- 10.2.2.1. Overview

- 10.2.2.2. Products

- 10.2.2.3. SWOT Analysis

- 10.2.2.4. Recent Developments

- 10.2.2.5. Financials (Based on Availability)

- 10.2.3 Hardwood Line Manufacturing Co

- 10.2.3.1. Overview

- 10.2.3.2. Products

- 10.2.3.3. SWOT Analysis

- 10.2.3.4. Recent Developments

- 10.2.3.5. Financials (Based on Availability)

- 10.2.4 Almco

- 10.2.4.1. Overview

- 10.2.4.2. Products

- 10.2.4.3. SWOT Analysis

- 10.2.4.4. Recent Developments

- 10.2.4.5. Financials (Based on Availability)

- 10.2.5 Mass Finishing Inc

- 10.2.5.1. Overview

- 10.2.5.2. Products

- 10.2.5.3. SWOT Analysis

- 10.2.5.4. Recent Developments

- 10.2.5.5. Financials (Based on Availability)

- 10.2.6 Guyson Corporation

- 10.2.6.1. Overview

- 10.2.6.2. Products

- 10.2.6.3. SWOT Analysis

- 10.2.6.4. Recent Developments

- 10.2.6.5. Financials (Based on Availability)

- 10.2.7 OC Oerlikon Management AG

- 10.2.7.1. Overview

- 10.2.7.2. Products

- 10.2.7.3. SWOT Analysis

- 10.2.7.4. Recent Developments

- 10.2.7.5. Financials (Based on Availability)

- 10.2.8 C Uyemura & Co Ltd

- 10.2.8.1. Overview

- 10.2.8.2. Products

- 10.2.8.3. SWOT Analysis

- 10.2.8.4. Recent Developments

- 10.2.8.5. Financials (Based on Availability)

- 10.2.9 POSCO

- 10.2.9.1. Overview

- 10.2.9.2. Products

- 10.2.9.3. SWOT Analysis

- 10.2.9.4. Recent Developments

- 10.2.9.5. Financials (Based on Availability)

- 10.2.10 Sequa (The Carlyle Group)

- 10.2.10.1. Overview

- 10.2.10.2. Products

- 10.2.10.3. SWOT Analysis

- 10.2.10.4. Recent Developments

- 10.2.10.5. Financials (Based on Availability)

- 10.2.11 OTEC Precision Finish Inc

- 10.2.11.1. Overview

- 10.2.11.2. Products

- 10.2.11.3. SWOT Analysis

- 10.2.11.4. Recent Developments

- 10.2.11.5. Financials (Based on Availability)

- 10.2.12 Linde plc

- 10.2.12.1. Overview

- 10.2.12.2. Products

- 10.2.12.3. SWOT Analysis

- 10.2.12.4. Recent Developments

- 10.2.12.5. Financials (Based on Availability)

- 10.2.13 Luster-on Products Inc

- 10.2.13.1. Overview

- 10.2.13.2. Products

- 10.2.13.3. SWOT Analysis

- 10.2.13.4. Recent Developments

- 10.2.13.5. Financials (Based on Availability)

- 10.2.14 A E Aubin Company

- 10.2.14.1. Overview

- 10.2.14.2. Products

- 10.2.14.3. SWOT Analysis

- 10.2.14.4. Recent Developments

- 10.2.14.5. Financials (Based on Availability)

- 10.2.15 Giant Finishing Inc

- 10.2.15.1. Overview

- 10.2.15.2. Products

- 10.2.15.3. SWOT Analysis

- 10.2.15.4. Recent Developments

- 10.2.15.5. Financials (Based on Availability)

- 10.2.1 TIB Chemicals AG*List Not Exhaustive

List of Figures

- Figure 1: North America Automotive Metal Finishing Industry Revenue Breakdown (undefined, %) by Product 2025 & 2033

- Figure 2: North America Automotive Metal Finishing Industry Share (%) by Company 2025

List of Tables

- Table 1: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Type 2020 & 2033

- Table 2: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 3: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 4: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Region 2020 & 2033

- Table 5: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Type 2020 & 2033

- Table 6: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 7: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 8: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 9: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Type 2020 & 2033

- Table 10: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 11: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 12: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 13: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Type 2020 & 2033

- Table 14: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 15: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 16: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Country 2020 & 2033

- Table 17: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Type 2020 & 2033

- Table 18: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Application 2020 & 2033

- Table 19: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Geography 2020 & 2033

- Table 20: North America Automotive Metal Finishing Industry Revenue undefined Forecast, by Country 2020 & 2033

Frequently Asked Questions

1. What is the projected Compound Annual Growth Rate (CAGR) of the North America Automotive Metal Finishing Industry?

The projected CAGR is approximately 4%.

2. Which companies are prominent players in the North America Automotive Metal Finishing Industry?

Key companies in the market include TIB Chemicals AG*List Not Exhaustive, Honeywell International Inc, Hardwood Line Manufacturing Co, Almco, Mass Finishing Inc, Guyson Corporation, OC Oerlikon Management AG, C Uyemura & Co Ltd, POSCO, Sequa (The Carlyle Group), OTEC Precision Finish Inc, Linde plc, Luster-on Products Inc, A E Aubin Company, Giant Finishing Inc.

3. What are the main segments of the North America Automotive Metal Finishing Industry?

The market segments include Type, Application, Geography.

4. Can you provide details about the market size?

The market size is estimated to be USD XXX N/A as of 2022.

5. What are some drivers contributing to market growth?

Increasing Requirement for Durable. Wear-resistant. and Long-lasting Metal Products; Other Drivers.

6. What are the notable trends driving market growth?

Automotive Segment to Dominate the Market.

7. Are there any restraints impacting market growth?

Environmental Restrictions on Some Chemicals; Increasing Replacement of Metal by Plastics; Impact of COVID-19 Pandemic.

8. Can you provide examples of recent developments in the market?

In May 2019, Guyson corporation has announced the availability of a new metal finishing technology called Multiblast 3D. This is a blasting chamber tailored to post-process 3D printed parts for HP Jet Fusion 500/300 Series 3D printers.

9. What pricing options are available for accessing the report?

Pricing options include single-user, multi-user, and enterprise licenses priced at USD 4750, USD 5250, and USD 8750 respectively.

10. Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in N/A.

11. Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "North America Automotive Metal Finishing Industry," which aids in identifying and referencing the specific market segment covered.

12. How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

13. Are there any additional resources or data provided in the North America Automotive Metal Finishing Industry report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

14. How can I stay updated on further developments or reports in the North America Automotive Metal Finishing Industry?

To stay informed about further developments, trends, and reports in the North America Automotive Metal Finishing Industry, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Methodology

Step 1 - Identification of Relevant Samples Size from Population Database

Step 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note*: In applicable scenarios

Step 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

Step 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence